Contrinex reputation for high-performance inductive sensors with many unique benefits has been further enhanced by its innovative SMART sensors, which combine a microcontroller with the sensor’s sophisticated ASIC to add on-board processing to “Measure, Monitor, Configure and Predict” – They offer machine builders the ability to program a customised sensor …

Read More »Contrinex don’t need to soft-soap hand-wash manufacturers about performance of metal M18 Photoelectric Sensors

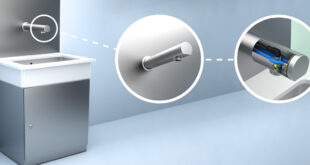

The past couple of years have seen an explosion in the popularity of non-contact hand-washing units. The manufacturers of these soap and water dispensers need robust, reliable and affordable sensors to detect the presence of the user’s hands. Traditionally these systems have used two sensors for accurate triggering, but a …

Read More »Contrinex inductive and fork sensors ‘keep the lid on’ ketchup bottles

Some of the most compelling examples of automation are in food packaging, where the extensive use of high-speed automation means that equipment performance and reliability are valued because line stoppages are both costly and time-consuming. Contrinex Photoelectric Fork and Inductive sensors are trusted to ‘keep the lid on’ and to …

Read More »Contrinex Cubic C23 700 Series inductives speed up robots and indexing table

Automated assembly systems are increasingly used for high volume assembly operations because of their ability to remove labour and also eliminate the potential of assembly errors. Rugged inductive sensors from Contrinex, available from PLUS Automation, help provide fault-free assembly and minimise downtime by reliable detecting the presence and position of …

Read More »Contrinex washdown rated 700 Series Inductives help ‘Turnover a New Leaf’ and keep a compost machine ‘On Track’

Agriculture is increasing its use of complex automation in its machinery and an unusual example application is in the tracks of composting machines. Contrinex’s uniquely robust V4A/ 316L stainless-steel sensors, available from PLUS Automation, are trusted to operate reliably inside the track drive rotor. Withstanding dust, humidity and high temperatures, …

Read More »Contrinex stainless-steel Smart sensors withstand extreme environments

Contrinex’s ground-breaking family of SMART inductive sensors, are now available from PLUS Automation with their uniquely robust 700 Series technology. Featuring a housing machined from a single piece of stainless-steel (V2A /AISI 303) and unique technology that provides robustness to survive extreme environments and including being used to hammer nails …

Read More »Contrinex M12 and M18 Metal-Bodied Photoelectrics launch at SPS Exhibition

In a sneak peek of being announced at the upcoming SPS Exhibition in Hannover, Contrinex will launch metal-bodied M18 sized photoelectric sensors which feature the same exclusive ASIC technology as their plastic-bodied counterparts. Contrinex’s plastic-bodied ‘M18PA’ sensors, available from PLUS Automation, have proved to be very popular because they combine …

Read More »Contrinex analogue inductives smooth the ride on tram suspensions

The speed and precision of Contrinex’s analogue inductive sensors are trusted in a diverse range of applications and industries and one such example is rail transportation. A German technology-leading manufacturer of sustainable urban transportation systems uses them to help it ensure safety and efficiency to optimise the performance of its …

Read More »Precision high-speed measurement with Contrinex long-range analogue inductives manages web tension

A manufacturer of textile handling machines trusts the speed, precision and reliability of Contrinex’s long-range Analogue Inductive sensors to measure the small changes in the position of a ‘dancer’ roller or ‘follower’, which follows the fabric web’s position and so indicates the web’s tension. The sensor’s precision measurement is fed …

Read More »Contrinex inductive sensors check the presence and position of workpiece carriers

Automation is extensively used throughout automotive assembly operations to transfer components between multiple production lines. In this application, the workpiece is lifted from its original carrier and placed onto a new one where sensors on the roller conveyor check its position. Contrinex’s uniquely robust 700 Series inductive sensors, available from …

Read More » Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control