Whilst Contrinex is renowned for the performance and robustness of its Weld-immune inductive sensors they continue to expand their offering with the introduction of an ACTIVSTONE ceramic-coating to offer the highest level of weld-spatter resistance. The high-performance ceramic material forms a durable, non-stick coating on all external surfaces of the …

Read More »Contrinex’s precision analogue inductive sensors call ‘time’ on timing belt errors

The precision and repeatability of Contrinex’s analogue inductive sensors, available from PLUS Automation, are trusted by a manufacturer of industrial timing belts to measure the position of steel reinforcing bands embedded within the belts. Two of these long-range, high-resolution sensors are mounted above either end of the extruded belt profile …

Read More »Contrinex inductive sensors help UK’s ports with ‘heavy lifting’

The UK’s busiest container ports handle over 1.5 million shipping containers per year and so rely on the high performance and reliability of their container-handling cranes. Contrinex’s rugged ‘600 Series’ inductive sensors play a key part in this, being trusted to prevent the crane’s carriage from travelling outside preset limits. …

Read More »Contrinex uniquely robust inductives help with the ‘Heavy Lifting’

An affordable solution was required to unload bulk cargo from a shipping container and so an attachment for a forklift truck was developed by a material handling company. The attachment uses Contrinex’s uniquely robust ‘700 Series’ inductive sensors to detect the position of the forks, because of their vibration, impact …

Read More »Contrinex long-range inductives ensure no need to ‘Cry in Your Beer’

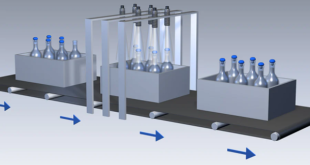

Imagine the disappointment, if when you opened a cardboard case of 12 bottles of beer, you found that it only contained 11 bottles. Perhaps it would be even worse if the bottles were not drinkable because their caps were missing. To ensure that consumers are not disappointed and that retailers …

Read More »Contrinex extended distance inductives ‘as cute as a button’ in automotive test equipment

The demanding quality standards of the automotive industry require a manufacturer to inspect the control knobs they manufacture for in-car audio systems, before shipment to the car assembly plants. The presence of a small metal washer that can occasionally become dislodged from inside each knob is therefore checked using a …

Read More »Contrinex 500 Series extended distance inductives are a ‘Jack of all Trades’ on bridge construction

Prefabrication is increasingly common in civil engineering, with for example bridges being constructed from prefabricated bridge elements lifted by mobile cranes onto support columns. To adjust the height of the bridge beams for assembly, heavy-duty hydraulic cylinder jacks support the ends of each beam. Each jack has a metal bracket …

Read More »Contrinex’s robust inductives ensure positioning of workplace carriers on conveyor

Automotive manufacturing relies extensively on automation and hence the reliability of Contrinex’s uniquely robust and high-performance ‘700 Series’ inductive sensors. One such example is the assembly of engines, where cylinder heads are transferred for mounting on the engine. A robot lifts the workpiece off its original carrier and places it …

Read More »Contrinex long distance inductives keep sensors out of harms way

Automotive manufacturers and their supply chain provide a rich collection of automation projects, hence the reliance on the high-performance and reliability of Contrinex sensors. One such example is a manufacturer of switches, which need to ensure the presence of a metal washer. The assembly of electrical switches includes a dark …

Read More »Contrinex’s pressure rated inductives pack a punch

Cold-forming is a popular low-cost method for joining sheet metal using a punch-riveting press. To ensure reliable and fast bonding, a high-pressure rated Contrinex inductive sensor is trusted to control the press. The inductive sensor is mounted directly in the wall of a small pneumo-hydraulic cylinder where it detects the …

Read More » Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control