Contrinex’s fibre-optic sensors, available from PLUS Automation, are trusted to detect breakages in the manufacturer of steel cable used in automotive parking-brake systems. The cable is formed from multiple strands of steel wire being twisted together. There is potential during manufacture for the cable to break which can damage equipment …

Read More »Contrinex’s inductive sensors stop wind turbines ‘Getting in a Spin’

The unique robustness, reliability and long sensing range of Contrinex’s ‘700 Series’ inductive sensors, available from PLUS Automation, are trusted to provide accurate contactless speed measurement on wind turbines. Modern wind turbines operate continuously in remote, highly demanding environments. Exceptional reliability is essential as opportunities for maintenance are limited. Turbine …

Read More »Contrinex’s inductive sensors prevent overloading of hooklift truck arm

Contrinex’s extremely robust ‘700 Series’ inductive sensors are trusted to detect the position of the telescopic lifting arm on hook-loader trucks, ensuring that it is retracted, before the lifting sequence. Hooklift trucks utilise hydraulic systems with a lifting hook that quickly loads and unloads a demountable container. The unique mechanical …

Read More »Contrinex ultrasonic sensors help get to the ‘meat of it’ on a bin wash-line

Contrinex’s ultrasonic sensors are trusted by a meat-processing plant to check that bins are empty before washing. Their high performance and reliability enable the plant to increase its productivity and eliminate breakdowns when washing empty meat bins. An ultrasonic sensor is mounted above the conveyor, looking down at the bins …

Read More »What can IO-Link do for me? Fit for the future with Contrinex and IO-Link

Perhaps many of us can be guilty of thinking that Inductive Proximity and Photoelectric sensors ‘just’ give us an ‘On’ or ‘Off’, and don’t think of the ‘digital-world’ also offered by the IO-Link communication protocol. Contrinex is respected as a manufacturer of high-performance sensors and often utilises unique technologies to …

Read More »Contrinex DGI light detection grids used for Poka-Yoke bracket assembly

To assure the correct assembly of a welded bracket for an automotive component supplier, Contrinex DGI infra-red light-grids are trusted to reliably detect each assembly as it is placed into a transport bin. This is part of a control system that verifies that the bracket’s welding cycle was completed correctly …

Read More »Contrinex knows how to use inductive sensors to check hose assemblies

A manufacturer of water heaters trusts Contrinex to quickly and reliably test stainless-steel-braided hydraulic hoses at the final stage of manufacture. Before the over-pressure test is applied, a system that uses several Contrinex inductive sensors checks each hose assembly to ensure that the correct mechanical parts have been fitted. Applying …

Read More »How to be smart with Contrinex’s SMART Inductive Sensors

Contrinex reputation for high-performance inductive sensors with many unique benefits has been further enhanced by its innovative SMART sensors, which combine a microcontroller with the sensor’s sophisticated ASIC to add on-board processing to “Measure, Monitor, Configure and Predict” – They offer machine builders the ability to program a customised sensor …

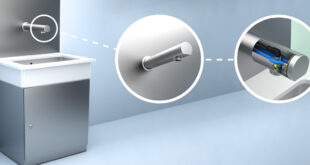

Read More »Contrinex don’t need to soft-soap hand-wash manufacturers about performance of metal M18 Photoelectric Sensors

The past couple of years have seen an explosion in the popularity of non-contact hand-washing units. The manufacturers of these soap and water dispensers need robust, reliable and affordable sensors to detect the presence of the user’s hands. Traditionally these systems have used two sensors for accurate triggering, but a …

Read More »Contrinex inductive and fork sensors ‘keep the lid on’ ketchup bottles

Some of the most compelling examples of automation are in food packaging, where the extensive use of high-speed automation means that equipment performance and reliability are valued because line stoppages are both costly and time-consuming. Contrinex Photoelectric Fork and Inductive sensors are trusted to ‘keep the lid on’ and to …

Read More » Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control