Within the medical arena there is increased pressure on budgets and financial accountability, with a significant trend for the sector to look again at how resources are used and where savings can be made.

Within the medical arena there is increased pressure on budgets and financial accountability, with a significant trend for the sector to look again at how resources are used and where savings can be made.

One of the largest expenditures in most hospitals is the cost of purchasing or producing the various medical gases needed, such as Medical Air, Nitrogen, Oxygen and Nitrous Oxide. Often the usage and consumption of these gases is neither monitored nor measured or, whenever it is done, it is often a crude estimation, inaccurate and recorded only by pen and paper.

Most hospitals rely on the rate at which the cylinders (in which the gas is supplied) empty to determine the amount and rate of gas used. There are of course many issues associated with this method, such as:

1. The amount of gas in a particular sized cylinder can vary greatly, even when directly delivered by the gas supplier

2. Total gas consumption and peak times of consumption cannot be accurately determined

3. Leaks can go undetected

4. Specific point of use consumption is impossible to determine

This makes it very difficult to manage costs overall and to assign invoicing costs to individual departments and sections.

Mass-Stream Instruments: http://www.bronkhorst.co.uk/en/products/gas_flow_meters_and_controllers/massstream_d6300/

A company specialising in the design, installation and maintenance of gas systems was asked to install the medical gas network in a new hospital. An approach was made to Bronkhorst UK Ltd for the supply of gas meters which could then be communication-linked to the building maintenance system.

Thermal mass flow Instruments with integrated multi-functional displays were offered to fulfil both the accuracy and reliability requirements. As a result of their through-flow measurement the thermal mass flow instruments offered additional benefits; no risk of clogging, no wear as there are no moving parts, minimal obstruction to the flow of the gas and hence ultra-low pressure drop, all based upon the fact that the instrument sesnor is essentially a straight length of tube.

In addition to the local integrated displays both 4…20 mA and RS232 output signals were available ensuring integration with the Building Management System (BMS). This gave the end user real time continuous data logging and remote alarming should the gas supply enter low- or high-flow status for any given event. As a double failsafe the instrument offers both on-board flow totalization and further hi/lo alarms.

The installation of the mass flow instruments for this hospital application provided the following benefits to the client:

1. On primary networks:

• Separated invoicing for hospital/clinic/laboratory departments sharing the same source of medical gas

• Monitoring and acquisition of consumption data

• Leak detection within gas line, safety vent and medical gas source

2. On secondary networks:

• Independent gas consumption invoicing between the health institution departments

• Over-consumption detection

• Monitoring and acquisition of consumption data

• Leak detection within gas line

Subsequent installations across Europe have followed the trend of increased accountability by installing a Mass Flow Meter for the incoming bulk delivery, obtaining a totalized flow reading and cross matching this to the bulk invoice. This could be useful in the event of inadvertent errors or typos when a bulk delivery invoice is being raised.

Application note: http://www.bronkhorst.co.uk/files/applications/a064_applicationnote_medical-gas-consumption.pdf

King’s Law and CTA meters, So how do these meters work?

The working principle of these CTA flow meters and controllers is based on King’s Law.

King’s Law can be attributed to L.V. King, who in 1914 published his famous King’s Law, mathematically describing heat transfer in flows. He used a heated wire immersed in a fluid to measure the mass velocity at a point in the flow. This can be described by the following formula:

P = P0 + C · ?mn

P … Heater power

P0 … Heater power offset at zero flow

C … Constant (device-dependent)

?m … Mass flow

n … dimensionless figure (type 0.5)

Wheatstone bridge and CTA meters

Wheatstone bridge and CTA meters

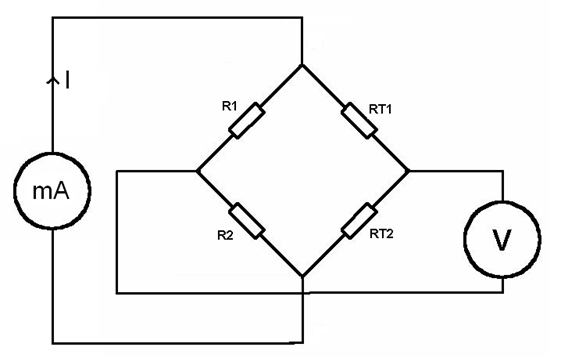

According to King’s Law, the greater the velocity of the gas across the probes, the greater the cooling effect. The electronics are realized with a Wheatstone bridge, which is an electrical circuit used to measure an unknown electrical resistance by balancing two legs of a bridge circuit, one leg of which includes the unknown component. Its operation is similar to the original potentiometer.

The two probes of the CTA sensor act as the legs of the Wheatstone bridge and as the heater probe is cooled by the fluid, the resistance of the probe is decreased and more energy is required to maintain the temperature difference.

The CTA sensor is aiming to keep this temperature difference (delta-T) between the two probes at a constant level. The flow rate and the heater energy required to maintain this constant delta-T are proportional and thus indicate the mass flow of the gas.

The actual mass flow rate is calculated by measuring the variable power required to maintain this constant temperature difference as the gas flows across the sensor.

The actual mass flow rate is calculated by measuring the variable power required to maintain this constant temperature difference as the gas flows across the sensor.

YouTube: https://www.youtube.com/watch?v=aIp7nyaiNS0&t=17s

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control