RS Components (RS) is sponsoring the PowerHab team from the University of Strathclyde as part of IGLUNA 2020, a pan-European initiative bringing together multidisciplinary students from across the globe in a collaboration to build solutions for a theoretical space habitat.

Coordinated by the Swiss Space Center, and now in its second year, IGLUNA 2020 covers a full range of topics, from the habitat conception and construction to life support systems, communication and navigation, power management, as well as human wellbeing and science. The purpose of IGLUNA 2020 is to demonstrate technologies capable of supporting a human-crewed lunar base, incorporating remote operation.

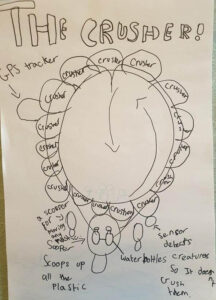

PowerHab is one of 15 teams across 10 countries selected to carry out this mission and is the only team from the UK. During the project, university students apply their knowledge to solve a technical challenge to develop a system capable of sustaining life in the harsh lunar environment, with its required power needs. To achieve this, the PowerHab team has devised a range of concepts that address the challenges of power harvesting, storage and distribution.

Isabella Mascarenhas, VP Grass Roots at RS Components, commented: “We’re delighted to support the PowerHab team with their fascinating project to develop practical solutions to create a habitable, safe lunar environment, and we’ve really enjoyed following their progress. IGLUNA is an exciting project that offers students an opportunity to participate in an international, collaborative, multidisciplinary project on a visionary space topic.”

Finlay Rowe from PowerHab added: “We would like to give a huge thanks to RS for partnering with us. Sponsorship such as this has been crucial to the success of our project, as it has allowed us to develop prototypes to the best of our abilities. This partnership has helped us by providing off the shelf components and lab equipment, without which prototype manufacturing would not have been possible.”

All of the participating teams were due to gather in Switzerland this week to demonstrate their projects. Due to COVID-19 restrictions this has been replaced by an online event, currently in progress from 10–19 July. The PowerHab team will present their prototypes as part of this ‘virtual field campaign’ at 10:00 BST on Thursday 16 July.

To watch the PowerHab presentation, or any of the remaining live-streamed events at IGLUNA 2020, visit the Swiss Space Center to find out more https://www.spacecenter.ch/igluna/.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control