The demand for high-accuracy meters in flow measurement has indeed grown over the years, driven by various factors such as stricter government regulations and the need for more precise measurements in critical applications. Manufacturers of flow measurement devices like Titan Enterprises are continually investing in research and development to introduce new technologies that enhance the accuracy and performance of their flow measuring instruments. This includes innovations such as improved sensor technology, advanced signal processing algorithms, and enhanced calibration methods.

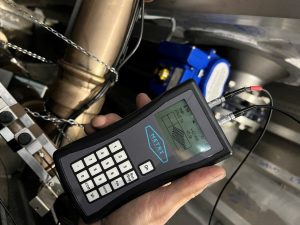

An important aspect to Titan Enterprises’ R&D is reviewing the performance of our flowmeters and delivering improvements in product design and materials that improves both the accuracy and repeatability (reliability) of these flow measurement devices.

“A high-quality flowmeter, carefully produced with a design and construction to tight tolerances and with high-quality materials as well as low wear and fatigue characteristics, is a precise meter with a quantifiable value of repeatability.” (R.C. Baker, 2016).

Repeatability and Accuracy are distinct terms used to define the performance and quality of a flowmeter.

So what is Repeatability?

The standard description is the flowmeter’s ability to produce the same result on repeated runs under identical operating conditions. Repeatability is often something that the design of the instrument defines and without excellent repeatability, a flowmeter cannot have good performance.

At Titan Enterprises we set our calibration rigs to record a certain number of pulses depending on the type of meter. The flow rigs accurately interpolate the rig and meter pulses and will not accept a reading unless it is within pre-set limits, usually set at 0.1% of repeated points. Repeatability is expressed as a ± percentage.

Repeatability can deteriorate at low flow rates so manufacturers may specify this value as a percentage plus a constant uncertainty value, or as a percentage of full-scale reading, rather than a percentage of measured flow rate.

Titan’s highly repeatable small turbine flow meters are successfully employed in batching processes and dispensing applications particularly within the food and beverage, chemical, medical and laboratory sectors. They have excellent repeatability (±0.1%) making them ideal for dosing systems and can be calibrated in-situ.

What is Accuracy?

Accuracy of a flowmeter relates to the quality of the measurement device and how close a measured reading is to the true flow. It is generally accepted that Accuracy is used as a qualitative term, where Linearity and Uncertainty measurements are the quantitative terms defining the accuracy of a flowmeter.

Linearity is usually defined by stating the maximum deviation of the reading over a stated flow range (e.g. ±1% of flow rate). It is the ability of the flow meter to remain within specified limits over its entire flow range determined by its design. The standard way of expressing linearity is error of reading. A frequently used alternative in some industry sectors is percentage of full-scale deflection or FSD.

Measurement uncertainty is the level of potential error in calibration, i.e. the range of values within which the true values lie with a specified probability. It is accepted that there is always a margin of error in any taken measurement and this uncertainty is quantified as a ± percentage.

Accurate flow rate measurement is influenced by an array of variables, including pressure, temperature, density and viscosity of the fluid. All of these factors are typically included in a calibration record. The very best calibration houses claim a measurement uncertainty as good as ±0.02%, though more typically ±0.1% when these factors are properly controlled.

The following images illustrate the relationship between repeatability and accuracy:

Overall, the trend towards higher-accuracy flow meters is likely to continue as industries evolve, and the demand for precise measurements in critical applications grows. This evolution is driven not only by regulatory requirements but also by the ongoing pursuit of process optimisation, efficiency gains, and improved product quality across various sectors.

Visit Titan Enterprises’ website for further information on flow measurement or to discuss specific technical applications, please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control

Outstanding Range and Precision

Outstanding Range and Precision InfraTec provides thermographic solutions for various fields of the automotive industry:

InfraTec provides thermographic solutions for various fields of the automotive industry:

Thermocouples

Thermocouples

With a library of 18, 00 designs we can offer a solution to most OEMs requirements.Product range is found in typical systems as

With a library of 18, 00 designs we can offer a solution to most OEMs requirements.Product range is found in typical systems as SOLENOID VALVES CRYOGENIC SOLENOIDS

SOLENOID VALVES CRYOGENIC SOLENOIDS METERING PUMPS

METERING PUMPS When immiscible liquids reside in the same vessel, eventually the lighter liquid rises to the top and the heavier settles to the bottom. This is the case with oil and water, where effective separation is critical to the productivity of upstream wells, processing plants and refinery/petrochemical complexes. Oil and water that undergoes emulsification is widely seen as the most difficult type of interface to control. A thick or dynamic emulsion layer creates challenges for one of the most widely utilized level technologies: Guided Wave Radar (GWR).

When immiscible liquids reside in the same vessel, eventually the lighter liquid rises to the top and the heavier settles to the bottom. This is the case with oil and water, where effective separation is critical to the productivity of upstream wells, processing plants and refinery/petrochemical complexes. Oil and water that undergoes emulsification is widely seen as the most difficult type of interface to control. A thick or dynamic emulsion layer creates challenges for one of the most widely utilized level technologies: Guided Wave Radar (GWR). based level instrumentation, there is an emphasis on expanding the use of

based level instrumentation, there is an emphasis on expanding the use of  The concentrated signal yields coaxial-like performance; yet it has an “open” design that is less susceptible to measurement errors due to media buildup or bridging. The PFA coated centre

The concentrated signal yields coaxial-like performance; yet it has an “open” design that is less susceptible to measurement errors due to media buildup or bridging. The PFA coated centre SEPARATORS

SEPARATORS