Fluke, a global technology leader in the manufacturer of compact, professional electronic test and measurement tools and software, today shares the top three trends that are enhancing operational efficiency in today’s industrial environments.

Challenges posed to industrial operations managers by the pandemic have now been superseded by the rising cost of energy, and the need to deliver on net zero ambitions. As the price of energy continues to increase, the need to reduce costs and deliver on shared sustainability goals intensifies for small-to-medium sized enterprises through to large corporations.

Paul Feenstra, Vice President Fluke EMEA, at Fluke said: “We are working together with our customers to help drive new initiatives to improve operations, increase efficiencies, and take reliability to a new level in the 21st century.”

- Reducing energy costs with upgraded technology and cloud-based data monitoring

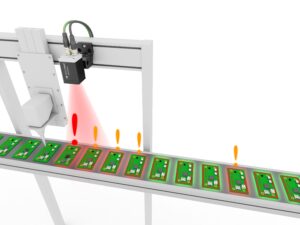

Approximately 90% of all companies use compressed air in some aspect of their operation, such that it is often referred to as the fourth utility. Recent developments in industrial acoustic imaging technology have enabled the fast identification of leaks in compressed air systems used in industrial and manufacturing environments. Fluke’s ii900 Industrial Acoustic Imager features an array of microphones, providing visualisation of sound field within an expanded field-of-view and on a distance of up to 70 meters, that enables maintenance teams to visually locate air leaks very quickly and accurately in compressed air systems.

Beyond the improvement of rugged handheld tools, monitoring practices are also evolving with the use of internet-connected instruments. Analysis and data is captured on a cloud platform allowing operators to monitor the key performance indicators (KPI) of compressed air systems including energy, electric power, flow, pressure and leakage flow. Fluke’s LeakQ™ Report Generator creates detailed air compressor leak reports from images captured by Fluke ii900 or the ii910 Precision Acoustic Imager and calculates the energy savings once the leaks are repaired.

- Using data to deliver predictive maintenance

For generations, maintenance professionals have used preventive maintenance to avoid equipment failures and turned to reactive maintenance when assets failed. With the emergence of Industrial Internet of Things (IIoT) technologies, maintenance professionals can now connect tools, software and sensors to collect, store and analyse multiple data sources in one place. The pandemic accelerated investment in technologies that make remote monitoring possible. The technology enables reliability and maintenance teams to meet up-time requirements no matter how fluid on-site staffing might be. The trend for remote monitoring will continue, with small scale operations turning to remote condition monitoring services.

Artificial intelligence (AI) and machine learning (ML) have held the promise to quickly identify trends and adapt quickly to changing operational conditions. Software armed with prescriptive analytics is finally meeting up with modern condition monitoring hardware to spark a revolution in the use of AI/ML in maintenance operations.

Now a new race has emerged to pair that hardware and software with ML and AI algorithms. Companies, like Fluke, are working to combine technologies so that the software can identify trends, recognise data patterns and make specific recommendations for equipment maintenance.

- Digital SI speeds integration of critical equipment measurements

The accelerated uptake in digital measurement solutions for industrial applications can save time and money, whilst facilitating a shift towards predictive maintenance for systems. Although modern measurement digital devices are typically not fit-and-forget solutions, the increase in digital measurement solutions paves the way for verification technologies that can help to reduce the maintenance burden on personnel, without compromising on accuracy or reliability.

Digital SI (International System of Units), an initiative created as part of the industry 4.0 revolution, relates to the creation of a globalised system to transmit calibration certification information electronically. This is critical as the exchange of data and the data itself are the basis of highly automated industrial processes. The system ensures measurement traceability from all calibrations performed and enables sharing of information in a paperless manner. This speeds up the integration of measurements that can be performed using critical test equipment as part of an integrated factory enhancing maintenance efficiency and plant efficiency.

“The tests we have faced within the last 24-36 months is delivering a growing awareness among top management that fundamental changes in maintenance best practice need to occur in order to protect the bottom line,” said Paul Feenstra.

“This is music to the ears of progressive industrial managers who have been advocating for investments to improve efficiencies and reliability of systems. Now is the time to make the case to adopt innovative technologies, tools, and processes to ensure your company maintains a competitive edge and thrives in this new environment.”

For more information about Fluke’s specialist products and services, go to: https://www.fluke.com/en.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control