A Yorkshire engineering specialist is using digital technology to help deliver a 12% weight saving for crucial aerospace parts.

MetLase, which employs 30 people at its state-of-the-art facility in Rotherham, has worked with the Advanced Manufacturing Research Centre (AMRC) to complete a series of research trials that are applying the use of smart positioning to ‘lightweight’ structural airframe components.

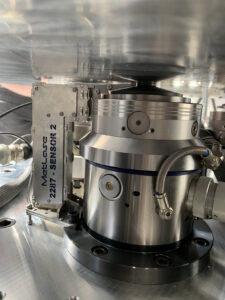

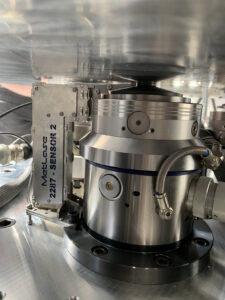

Using the power of its MetElements hardware and software framework, the company has implemented a series of specialised distance senor units to existing fixturing within a machine tool.

The eight sensor modules used low-cost ‘smartphone grade’ sensors and were also designed so that they did not interfere with the cutter path.

“The 7000-grade aluminium used in these types of airframe components is renowned for its internal residual stresses and its habit of warping during machining; especially if the component is thin walled, as this lowers the geometric stiffness of the final component,” explained Richard Gould, Business Development Manager at MetLase.

“We have a strong relationship with the AMRC, so used this collaborative partnership to work with its engineers to explore how sensors could be used in adjusting the machining process in real time, compensating for any warping as the part is being cut, and delivering better geometric accuracy in the final component.”

He continued: “Leveraging the power of MetElements, we were able to give live feedback about the component’s geometric condition during the milling process, with a 3D display created that showed how the component was distorting in near real-time (60Hz).

“The results of the trials delivered a 12% reduction in the final part weight due to the reduction in wall thickness.”

Daniel Smith, Technical Fellow in the Aerostructure and Landing Gear Team at the AMRC, added his support: “The project successfully demonstrated the power of adding sensing equipment to existing industrial processes, and the positive impact harvesting live in-process data can have when validating model data and ultimately improving the quality of the output component geometry.

“MetLase has been instrumental in the implementation of sensor technology throughout this project, working with us from the start and then supporting us with its own design, engineering, and digital manufacturing expertise.

“It has delivered several tangible results, but importantly has given us a solid use case on how industry could retrofit low-cost smart i4.0 sensing to existing off-the-shelf-machining equipment.”

MetLase has been embracing digital manufacturing since its inception in 2015 and now boasts a client base of tier 1s, primes and Original Equipment Manufacturers (OEMs) from the automotive, aerospace, Formula One, maritime and power generation worlds.

Stewart Lowth, Product Development and Innovation Manager at MetLase, concluded:

“MetElements gives us an adaptable platform for any connected technologies to communicate with each other, whether they are traditional industrial automation sensors or modern small-factor smartphone style sensors.

“Just like on the AMRC project, this digital flexibility allows the right sensing solution to be used for the right job; saving money for SMEs and large organisations alike.”

For further information, please visit www.metlase.com

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control