The SHSLab is a powerful and comprehensive wavefront measurement solution from Micro-Epsilon. Developed by Optocraft GmbH, a member of the Micro-Epsilon group of companies since 2018, SHSLab Shack-Hartmann wavefront sensors are used for applications such as optics testing, optics alignment and laser beam characterisation. Wavefront sensors are used in production and R&D in optics manufacturing, laser industries, astronomy and space applications, as well as by contact- and intra ocular lens manufacturers, including mobile phone optics, microscope and photographic lenses.

A typical application is for the alignment of optical systems, where wavefront guiding facilitates and speeds up the alignment process significantly. The following application describes the alignment of a collimation lens in front of a light source, and the set up of a Kepler telescope. The discussed principle can be applied to many alignment applications, not just the specific example described below.

Alignment of collimating lens and Kepler telescope

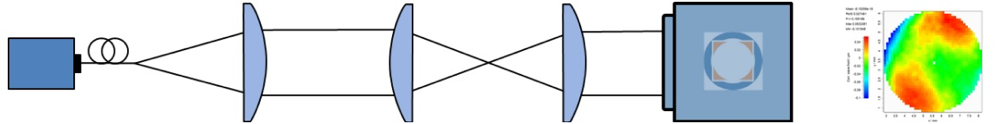

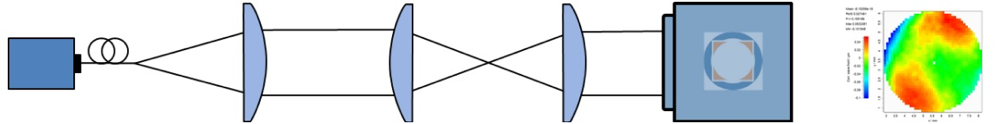

In the test set up, a fibre-coupled LED is used emitting at 625nm. In the first step, the fibre end and the SHSLab Shack-Hartmann wavefront sensor (WFS) are mounted on a rail on an optical table. The WFS detects the spherical wave emitted by the fibre. In this situation, the wavefront curvature radius measured by the WFS is equal to the distance between the fibre end and the micro-lens plane of the WFS. This means it can be used to align the correct axial position of the fibre end.

A collimating lens is placed (focal length ƒ=60mm) in front of the fibre. First, the lens is aligned in the lateral direction by minimising the wavefront tilt α, which is directly related to the lateral misalignment Δx between the lens and the fibre end: Δx = ƒ . tan α. Next, the lens is aligned in the axial direction by minimising the spherical power of the wavefront (resp. wavefront defocus). The spherical power Dsp is directly related to the axial misalignment:

Using a relatively simple centering stage for x-y alignment of the collimating lens, the tilt can be reduced to 0.007mrad. By displacing the lens along the rail in the z-direction, the beam can be collimated and a wavefront curvature radius of Rwf ≥ 110m can be achieved (the achievable collimation is limited by the mechanical components of the setup, not by WFS measurement precision).

Now a Kepler telescope can be set up, which consists of two lenses with 40mm focal length. The first lens is mounted 40mm in front of the WFS, and the second lens is initially mounted 80mm in front of the first lens. In this roughly pre-aligned state, the wavefront shows a tilt of 0.5mrad and a curvature radius of 0.85m. Aligning the second lens of the Kepler telescope in the lateral and axial directions, again tilt is minimised and spherical power of the wavefront is transmitted through the telescope. In this way, the Kepler telescope can be quickly set up and precisely aligned to an afocal configuration. If tilt and defocus resulting from residual misalignments are subtracted, it is found that the setup consisting of collimating lens and Kepler telescope has a “corrected” wavefront rms of 0.027µm (on 5mm pupil diameter). This corresponds to a Strehl ratio of 0.92, i.e. the setup is well diffraction limited.

Sensitivity of the alignment signal

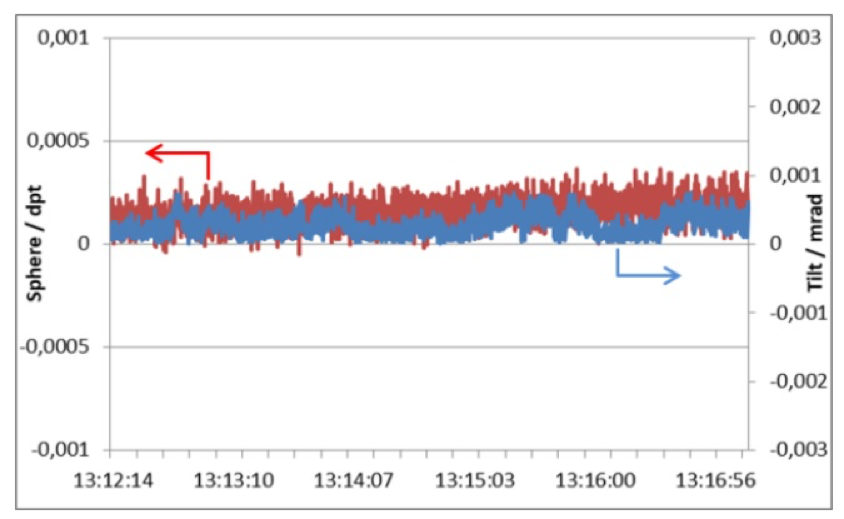

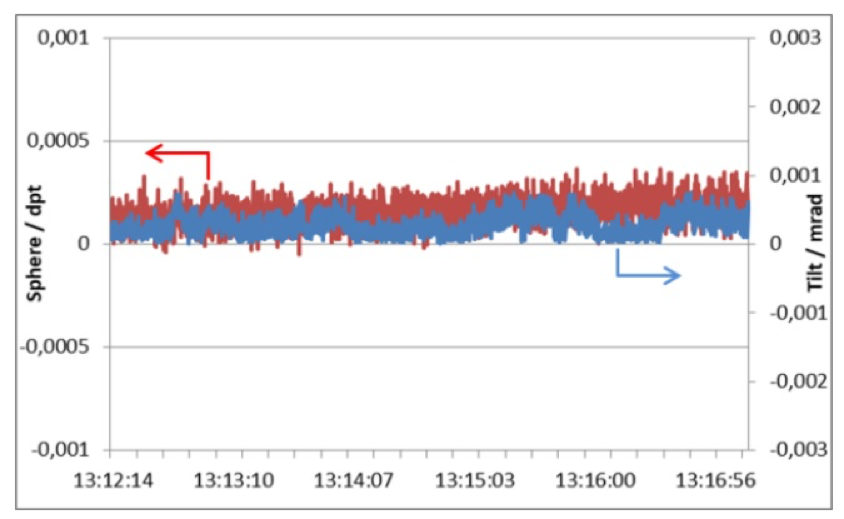

In the above scenario, where the light emitted by the fibre is collimated by the collimating lens, the sensitivity of the wavefront tilt and refractive power need to be considered. To assess stability, the wavefront data is continuously recorded for 5 minutes, and the standard deviation of the temporal signals are calculated (shown in the graph below):

σTilt = 0.2µrad; σD = 0.06mdpt. Using the above noted relations between lateral displacement and tilt, and between axial displacement and curvature radius, these numbers translate into a theoretical sensitivity of the focus position measurement of ca. 12nm in the lateral direction and ca. 220nm in the axial direction (for a focal length of ƒ=60mm of the collimation lens).

Phase plate and spatial filtering

In the second stage of the experiment, a phase plate (optical window with certain surface aberrations) is placed as a test object in the object plane of the telescope. The WFS now detects the aberrations of the collimating lens, the Kepler telescope and of the phase plate.

By recording a reference measurement of the system without the phase plate first, the aberrations of the system (spot reference) can be subtracted to obtain the wavefront that carries only the aberrations of the phase plate.

Many applications make use of spatial filtering methods to reduce wave aberrations. To demonstrate the effect of spatial filtering on the transmitted wavefront, a pinhole with 100µm diameter can be inserted at the Fourier plane of the Kepler telescope, thereby low-pass filtering the wave generated by the phase plate (the pinhole must be aligned in the x-, y- and z-axis by minimising wavefront rms). The effect of this pinhole is small; the corrected wavefront rms decreases from 0.1µm to 0.09µm. So the 100µm pinhole is replaced by a 50µm pinhole. The corrected wavefront rms distinctly decreases to 0.06µm. When replacing the 50µm pinhole with a 30µm pinhole, the corrected wavefront rms decreases further to 0.02µm. The PSF shown below is calculated from the corrected wavefront with an added refractive power representing the effect of the telescope lens with 40mm focal length.

The Optocraft wavefront sensors are distinguished by their high speed, single-shot measurements, excellent unreferenced accuracy, extreme dynamics and broad spectral ranges. They are also able to measure wavefronts with very strong higher order aberrations. They can measure large tilt angles and strongly defocused beams. They offer high intrinsic stability and reliability, powerful, customisable evaluation software and are versatile and flexible in usage. Optocraft’s systems are in operation in many demanding customer applications.

For more information on the SHSLab wavefront sensors from Micro-Epsilon, please visit www.micro-epsilon.co.uk or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email mailto:info@micro-epsilon.co.uk

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control