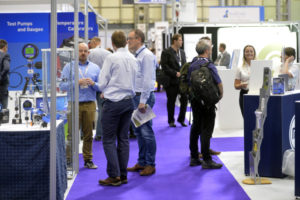

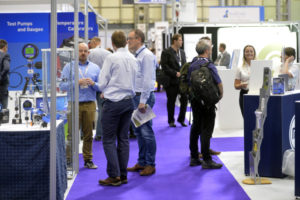

Sensors & Instrumentation Live returns to the NEC, Birmingham for its special 10 year anniversary show on 25 and 26 September 2019. Located in Hall 2 and co-located with the TCT Show, the exhibition brings together the best instruments and sensors from market-leading companies. Registration for the UK’s only dedicated sensors exhibition is free and your ticket will get you access to training, demonstrations and a lot more.

For the last ten years, Sensors & Instrumentation Live has been bringing visitors the latest sensor technology that has been driving this connectivity. Mouser Electronics is the headline sponsor of this year’s special anniversary event, taking place at the NEC, Birmingham on 25 and 26 September 2019. The company’s sensors portfolio is highly complementary to the exhibition. Graham Maggs, Mouser Electronics’ VP Marketing Europe, explains why Sensors & Instrumentation Live is a must attend event for anyone interested in sensor solutions and the connected world: “Sensors & Instrumentation Live is important to the industry because it provides a vital and vibrant forum for discussion. In particular, at Mouser we are seeing huge interest in our burgeoning portfolio of sensor solutions. We believe that this is because of the realisation and uptake of a huge number of designs which come under the umbrella heading of IoT. Every IoT implementation – smart home/ factory/ office/city, remote diagnostics, autonomous vehicle, smart grid – relies on data. Therefore, many IoT designs start with the choice of sensor. Temperature, speed, pressure, flow, gas detection, movement, person detection, light – these are just some of the sensor types offered by Mouser. We are delighted to sponsor Sensors & Instrumentation Live and look forward to a lively event.”

Sensors are among many of the technologies that will be on display at the exhibition. Bronkhorst, Charcroft Electronics, Keller, Kistler Instruments and Rheintacho are just some of the market-leading companies that will be displaying their products at Sensors & Instrumentation Live 2019.

Kistler Instruments will be showing KiDAQ, a new, modular data acquisition system. The modular design of KiDAQ makes virtually unlimited channels and distributed systems a reality whatever the application; industrial, laboratory, permanent and mobile applications.

Charcroft Electronics, a specialist distributor and manufacturer of electronic components for harsh and high-end applications, with an extensive linecard featuring many key manufacturers, will also be at the exhibition.

Commenting on Charcroft’s decision to exhibit at Sensors & Instrumentation Live, Kathryn Stevenson says: “It is important as a showcase for companies to demonstrate their capabilities, products and support available. It is an excellent opportunity to engage with customers as well as connect with potential customers, with specialised focus on the Sensor and Instrumentation market sector.”

The University of Birmingham’s Centre for Innovation in Advanced Measurement in Manufacturing (CIAMM) will also be represented at the show. The University of Birmingham collaborates with organisations of all sizes, from global corporates to local SMEs, with a focus on driving innovation through collaborative research partnerships. They form partnerships with business, to work on transformative projects and make important things happen.

Aware that the financial cost of generating new ideas, technologies and processes to help you achieve competitive advantage can be high, CIAMM sits firmly amongst the leading research universities in the UK and plays a pivotal role in facilitating economic development through its business support programmes.

Visitors to the University of Birmingham stand at Sensors & Instrumentation Live will receive specific details on the CIAMM business support programme.

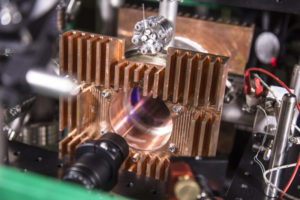

Julian Moore, business engagement manager, CIAMM, says: “Sensors & Instrumentation Live is important to the industry as there is natural parallel with the exciting developments occurring within the area of quantum technologies.”

Moore adds: “Sensors are found in most every day products and play a vital role in supporting an increasing range of data requirements. It is essential this exhibition continue to highlight the latest technology in the fields of test, measurement and control, so businesses can explore and exploit the great opportunities that exist, particularly in rail, transport and telecommunications.”

KDP Electronic Systems will be exhibiting its products at the event. The company provides solutions to customers in the commercial, defence, transportation, aerospace and industrial markets. In supporting these markets, KDP represents in the UK a wide range of industry standard products from renowned global companies, Wilcoxon Sensing Technologies, CTC and Vigor Technology.

Malcolm White, KDP, says: “The Sensor & Instrumentation Live Show provides the ideal platform for promoting products of the highest quality. KDP are committed to provide the very best customer support and service. It is essential to monitor asset health, keep valuable machines running, minimising downtime and reducing costs.”

Another exhibitor at Sensors & Instrumentation Live has reasons to celebrate this year. Like the exhibition, Rheintacho UK has a special anniversary in 2019. The company celebrates its 100th anniversary this year.

At the show, Rheintacho UK is going to show its newest products. One of them is the new M8 rotational speed sensor which is not only one of the smallest available worldwide, but also includes temperature measurement. This of course make life easier for any engineer who requires both features.

In addition, the company is going to show the newest member of its stroboscope family, the LED PocketStrobe laser. This portable strobe has a patented integrated laser which enables auto synchronisation and is among the brightest available for smaller handheld devices. Rheintacho is going to be demonstrating this strobe at the fair in Innovation in Action.

On top of that, the company’s eddy current tachometers are now ATEX certified offering the market safe measurement in hazardous areas. This product family includes many sizes in 14 different tachometer types and includes different types of gearboxes.

Commenting on the exhibition, a representative from Rheintacho UK says: “It offers the opportunity to promote innovation in the sensors industry beyond application boundaries. The networking possibilities also promote collaboration and referrals.”

Sensonics is another company that will be showcasing its products at Sensors & Instrumentation Live. The company is an expert in vibration, displacement and speed monitoring solutions.

Jason Kingdom, sales manager at Sensonics, says: “Sensonics is committed to developing the most innovative and effective solutions for vibration, position and speed instrumentation for critical machine condition monitoring applications in power generation and process manufacturing industries around the world. This is Sensonics’ first time exhibiting at the Sensors & Instrumentation Live show, it seems to be a great opportunity for us to meet a new group of visitors in a very relevant sector gaining excellent exposure for our wide standard product range as well as highlighting our bespoke engineering solutions capability.”

These companies are just a small selection of the exhibitors that will be at this year’s Sensors & Instrumentation Live.

Innovation Showcase

As well as seeing products on stands, visitors also have the opportunity to view a selection of the best technology in the Innovation Showcase. The ever popular Innovation Showcase, sponsored by Bronkhorst, provides an assembly of the most cutting-edge products and solutions available from exhibitors. Visitors can get hands-on with devices and make sure they do not miss out on a single thing. Exhibitors lined up to take part in the Innovation Showcase include Charcroft Electronics, Mantracourt, Bronkhorst, Broadband Technology 2000, Rheintacho, Keller, SIKA, Aerodyn and Devtank.

The Innovation Showcase is just one of the feature areas at Sensors & Instrumentation Live. And to celebrate the event’s 10 year anniversary, the exhibition will see the introduction of new feature areas that will explore the latest technological innovations and provide insight from top organisations on how to grow businesses or streamline productivity.

Sensing innovation – the Engineering Symposium

This year, Sensors & Instrumentation is teaming up with DJB Instruments to deliver CPD-accredited training that will help you to develop your understanding of sensors and instruments to improve the quality of your data. The training is driven by sensor innovation and the very latest in engineering. DJB has brought together a team of speakers from leading technology and engineering companies from around the world to present a two day programme of technical seminars.

John Tyrrell, managing director at TTS Systems, will be presenting “Strain Gauge Loadcells – the basics of use…”. Whether you are measuring load, weight or force you will be using a loadcell. Now it may be a foil or silicon strain gauge, aluminum, steel or exotic material, sealed or not, to name but a few design features. But do not forget the fundamentals – otherwise the data will be worthless! Tyrrell will explain the basics of strain gauge loadcell use to help you improve the quality of your data.

Ben Haest, Quality Electronics Design, Luxembourg, will be delivering the seminar “Automation in Environmental Testing”. Other topics will include: “Challenges of developing wireless sensor communication” and “Kurtosis control impacts on reality of test simulation”.

Innovation in Action

Innovation in Action, sponsored by PCB Piezotronics, is a new feature introduced for the 10 year anniversary event. Innovation in Action will see live demonstrations of some of the best products on the market. As well as giving you the opportunity to see how these products work in real life, you can have your questions answered by the experts in person.

Companies already confirmed to speak in Innovation in Action include PCB Piezotronics, Devtank, Kistler, SIKA and Bronkhorst. PCB Piezotronics is a designer, manufacturer, and global supplier of accelerometers, microphones, force, torque, load, strain, and pressure sensors, as well as the pioneer of ICP technology. This instrumentation is used by design engineers and predictive maintenance professionals worldwide for test, measurement, monitoring, and control requirements in automotive, aerospace, industrial, R&D, military, educational, commercial, OEM applications, and more. You can see a live demonstration of PCB products in Innovation in Action.

Devtank will be demonstrating its new open source modular test product called HILTOP (Hardware In-the-loop Test Operating Platform). The platform contains an integral motherboard/controller adopting a flexible split architecture with 64bit ARM processor and parallel FPGA hardware acceleration if required. It has a High Speed Open-VTI backplane provides modular expansion using the Eurocard form factor and upgradeable FPGA SO-DIMM modules. A powerful 1.2GHz quad-core ARM Cortex CPU (Raspberry Pi Compute Module CM3-Lite) and ICE40 8K FPGA combo can be fitted as an option. All this comes packaged in a robust industrial grade instrumentation case built to last.

Devtank’s comprehensive flexible platform allows test, measurement and control solutions to be realised using numerous built in multi-channel interfaces such as USB2.0, LVDS, CAN-FD and RS485. It can be easily expanded to add new interfaces and capability using the Open-VTI backplane and Eurocard expansion format. Automated testing gives faster and more accurate measurements through optimised hardware and software integration to provide both electrical and functional test coverage of the device under test (DUT).

Bronkhorst is a leader in mass flow meter / mass flow controller technology for gases and liquids, pressure controllers and evaporation systems. Bronkhorst’s Damian Walker will be giving a demonstration of the company’s LDM (Liquid Dosing Module) in Innovation in Action. The LDM is a modular assembly of a Bronkhorst mini CORI-FLOW mass flow meter and a pump system, built together in a robust enclosure as a complete unit with integrated power supply and touch-screen interface. It is capable of very low flow continuous or batch dosing.

Enterprise Hub

As well as finding the instrumentation you need, Sensors & Instrumentation Live offers a prime opportunity to grow your business in the new Enterprise Hub. Representatives from key engineering institutions and organisations will give a series of invaluable presentations, giving visitors an insight into topics including funding, training, apprenticeships and standards as well as insight into how to make the most of supply chains.

Sensor City’s head of engineering, Daniel Watson, will be giving the talk ‘Sensor City – Inside a Global Innovation Hub’. Watson will introduce Sensor City by discussing its in-house laboratory facilities and technical expertise. He will also provide case study examples of sensors and IoT lab projects that have involved Sensor City. In addition, Watson will outline future plans for Sensor City and outline collaborative opportunities that are available.

The Defence and Security Accelerator (DASA) is one of the organisations signed up to speak in the Enterprise Hub. DASA finds and funds exploitable innovation to support UK defence and security quickly and effectively, and support UK prosperity. Andrew Peaty, innovation partner at DASA, will be leading the talk ‘Innovation for a Safer Future; the Defence and Security Accelerator’. Peaty will describe how innovators can work with DASA and what the initiative is looking for in applications for funding. He will also present the current competitions being run by DASA and give an overview of the likely future calls.

The Institution of Engineering & Technology (The IET) will also be sharing their expertise in the Enterprise Hub. Dan Canty, accreditation & awards manager at The IET, is going to give the talk ‘An introduction to apprenticeship and technician qualifications’. As well as providing an introduction to the qualifications, the talk will cover where to access information and support and how the IET supports engineering apprentices, providers and employers.

Another speaker lined up for the Enterprise Hub is Charlotte Horobin, membership director – Midlands & East of England, Make UK. In her talk ‘‘Making It Happen’ – A view from UK manufacturing and the challenges and choices that lie ahead’, Horobin will provide an overview of Make UK’s research of how the sector is faring in these challenging times and will explore some of the key hurdles that need to be capitalised on, turning them into opportunities such as skills, productivity and export.

Julian Moore, business engagement manager at the University of Birmingham’s Centre for Innovation in Advanced Measurement in Manufacturing (CIAMM), will be explaining how quantum theory is driving the development of more accurate, faster and portable technologies. CIAMM offers pre-funded assistance to help SMEs solve quality-related challenges through advanced inspection and measurement, enabling them to realise their new product aspirations. It delivers support by providing access to specialist expertise, world-class facilities and a wide network of collaborative partners. Find out how CIAMM can help you in the Enterprise Hub.

Other organisations that have already signed up to be at the event include the British Measurement & Test Association (BMTA), Engineering and Physical Sciences Research Council (EPSRC) and TTE Technical Institute and GAMBICA.

Register for your free ticket

Attendance to any of the seminars in the Enterprise Hub and Engineering Symposium as well as all of the other features is free to visitors. Your ticket will also get you access to the co-located TCT Show so register now by visiting www.sensorsandinstrumentationlive.co.uk.

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control