MMS Electronics Ltd (MMS-e) has available a range of small intelligent displays with optional touch-screens. The 2.8” EA eDIP128-6 (128×64) and 3.3” EA eDIP160-7 (160×104) are available in blue background with white characters and white background with black characters. (FSTN).

MMS Electronics Ltd (MMS-e) has available a range of small intelligent displays with optional touch-screens. The 2.8” EA eDIP128-6 (128×64) and 3.3” EA eDIP160-7 (160×104) are available in blue background with white characters and white background with black characters. (FSTN).

The EA eDIP intelligent displays enable companies to improve product to market time and reduce development cost. Within minutes of opening the box the EA eDIP displays function immediately. Pre-integrated with all driving electronics, flash memory, backlight drivers, I/O and optional touch-screen functionality, the display is ready to be connected by serial, SPI or I²C interface to the host processor or when using a simple level converter USB, RS-232 or RS-485 is available.

Engineers can create attractive layouts without writing lots of code. The displays offer integrated fonts with zoom function. New True-type fonts can be loaded to the onboard display memory with the free software tools. More than 112 embedded graphic commands are available to create impressive screen layouts. Drawing lines or boxes, bar graph, select portrait or landscape mode, 90º rotation, pull down menus, BMP, JPG or GIF bitmaps import and commands for the analogue touch–screen reduce the development time significantly. Bitmap pictures and macro programs can be stored on the display to be called up from the touch-screen or from a controller connected to the serial, I2C or SPI interface.

Engineers can create attractive layouts without writing lots of code. The displays offer integrated fonts with zoom function. New True-type fonts can be loaded to the onboard display memory with the free software tools. More than 112 embedded graphic commands are available to create impressive screen layouts. Drawing lines or boxes, bar graph, select portrait or landscape mode, 90º rotation, pull down menus, BMP, JPG or GIF bitmaps import and commands for the analogue touch–screen reduce the development time significantly. Bitmap pictures and macro programs can be stored on the display to be called up from the touch-screen or from a controller connected to the serial, I2C or SPI interface.

The display includes a terminal mode function where all incoming characters are displayed in ASCII format. (Except some of the control characters). By programming the power-on macro the terminal window size, font and font size can be pre-set. The power-on macro can for example also be used to display and animate the company logo while the main controller takes time to power up or is servicing other tasks.

The displays have 8 free programmable inputs and outputs. These can be used for connection to pushbuttons, switches or LED indication. Should extra outputs be required then the output port can be expanded. See datasheet for an example. Display supply voltage is +3.3V or +5V.

The displays have 8 free programmable inputs and outputs. These can be used for connection to pushbuttons, switches or LED indication. Should extra outputs be required then the output port can be expanded. See datasheet for an example. Display supply voltage is +3.3V or +5V.

An evaluation board EA EVAL-eDIP is offered to kick start developing with the intelligent displays. The evaluation board provides serial, I2C, SPI interface and also USB, RS232, and RS485. The DIP switches on the adapter boards allow test and set-up of the display address function. Eight push buttons and LED’s are connected to the display I/O. The USB port is used to power and communicate to the LCD development tools on the PC. Many code examples are included with the software.

The EA eDIP128 is the smallest display in the intelligent series. 6 display sizes up to 7.0” are available. (2.8”, 3.2”, 4.2”, 4.3”, 5.7” and 7.0”). The 3.2”, 4.3”, 5.7” and 7.0” are full colour TFT displays.

The EA eDIP128 is the smallest display in the intelligent series. 6 display sizes up to 7.0” are available. (2.8”, 3.2”, 4.2”, 4.3”, 5.7” and 7.0”). The 3.2”, 4.3”, 5.7” and 7.0” are full colour TFT displays.

The EA eDIPTFT displays include powerful commands for analogue rotary / gauge or bar graphs instruments. These instruments are generated with just a few simple commands. The eDIPTFT5.7 and EA eDIPTFT7.0 include a 1W amplifier for acoustic feedback into an 8-ohm speaker. Sound can be used for simple clicks, notes and warning messages.

MMS Electronics supplies stylish black bezels for all EA eDIP intelligent display. Two clips are supplied to attach the display to the bezel. Four studs are used to screw the bezel to the panel or enclosure.

MMS Electronics Ltd is a supplier of Electronic Assembly Gmbh LCD, TFT, OLED, ePaper, DOG chip-on-glass, eDIP intelligent displays, IcNexus Android OS displays with I2C and serial ports, display bezels, touch-screens and Storm keypads.

In addition MMS Electronics supplies sensor products from Smartec BV and Excelera.

-

SMT16030 Digital temperature sensors with PWM output.

-

SMT IRMOD09 Calibrated Infra-red temperature sensor,I2C output.

-

SMT SPD Digital and analogue pressure sensors.

-

SMT UTI Digital sensor transducers for resistive and capacitive measurements. THE SMT UTI has 16 modes and can measure capacitance starting at 0 to 2pF.

-

UFDC-1 Universal Frequency-to-Digital Converters with RS232, SPI and I2C interface. These transducers can measure frequency signals, RPM, pulse, PWM, phase shift with an accuracy of 0.0005%.

-

USTI-MOB Low power Universal sensor and Transducer Interface starting at 15 µA. Ideal for battery powered application.

-

USTI-EXT Universal sensor and transducer interface for extended temperature (-55ºC to +150ºC) for use in or near gearboxes, engines, exhaust systems and brakes.

Please contact MMS Electronics Ltd with your display or sensor enquiries.

Full display part numbers listed this article:

EA eDIP128W-6LWTP

EA eDIP128B-6LWTP

EA eDIP160W-7LWTP

EA eDIP160B-7LWTP

EA EDIP240J-7LWTP

EA EDIP240B-7LWTP

EA EDIP230J-8LWTP

EA EDIP320B-8LWTP

EA EDIPTFT32-ATP

EA EDIPTFT43-ATP

EA EDIPTFT57-ATP

EA EDIPTFT70-ATP

MMS Electronics Ltd

Tel 01943 877668

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control

Fluke, the global leader in portable electronic test and measurement technology, has developed Fluke TestGuide, a helpful free app for electrical installers, electrical engineers and maintenance professionals in the field. The app provides support for the most common measurements, providing step-by-step guides, for example, for RCD testing and measuring insulation. The TestGuide app shows electricians in short and clear steps what the actions are, what to look at and how to interpret the results. More information can be obtained at

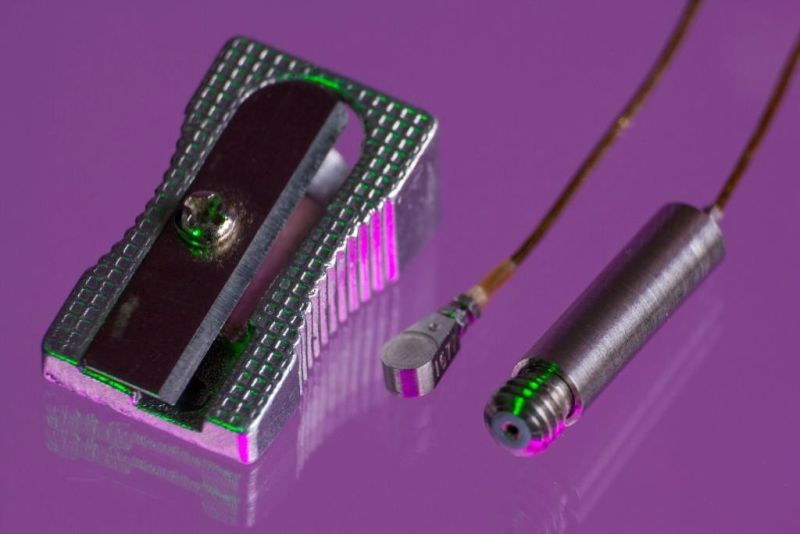

Fluke, the global leader in portable electronic test and measurement technology, has developed Fluke TestGuide, a helpful free app for electrical installers, electrical engineers and maintenance professionals in the field. The app provides support for the most common measurements, providing step-by-step guides, for example, for RCD testing and measuring insulation. The TestGuide app shows electricians in short and clear steps what the actions are, what to look at and how to interpret the results. More information can be obtained at  DJB Instruments (UK) Ltd announces the launch of the worlds smallest and lightest integral electronics piezo-electric (IEPE) stainless steel accelerometer. At just 5.7mm long, 3.5mm wide and just 2.3mm high the A/128/V weighs in at a miniscule 0.19grams making it virtually invisible to the item under test in terms of mass loading.

DJB Instruments (UK) Ltd announces the launch of the worlds smallest and lightest integral electronics piezo-electric (IEPE) stainless steel accelerometer. At just 5.7mm long, 3.5mm wide and just 2.3mm high the A/128/V weighs in at a miniscule 0.19grams making it virtually invisible to the item under test in terms of mass loading. New Cynergy3 website enables ‘live’ global stock check of products

New Cynergy3 website enables ‘live’ global stock check of products HBM is offering a series of

HBM is offering a series of  Sensor-Technik UK introduces the L03 pressure transducer. With its flush stainless steel diaphragm and compact construction, the L03 is designed with the food and beverage industry in mind. Mounted into a system via the weld-flange SF01, the L03 provides a safe, clean and reliable interface between monitoring and control systems, especially for level measurement.

Sensor-Technik UK introduces the L03 pressure transducer. With its flush stainless steel diaphragm and compact construction, the L03 is designed with the food and beverage industry in mind. Mounted into a system via the weld-flange SF01, the L03 provides a safe, clean and reliable interface between monitoring and control systems, especially for level measurement. As mobile machinery becomes more and more complex, the need for a logical and distributed control architecture is greater than ever before. In order to provide more input/output functionality without the need for an increased wiring loom and cost, Sensor-Technik UK offers the ESX-DIOS, a dedicated input/output slave module operating using the CANopen communications protocol.

As mobile machinery becomes more and more complex, the need for a logical and distributed control architecture is greater than ever before. In order to provide more input/output functionality without the need for an increased wiring loom and cost, Sensor-Technik UK offers the ESX-DIOS, a dedicated input/output slave module operating using the CANopen communications protocol. To complement its range of powerful and robust control hardware, Sensor-Technik UK introduces the Opus A6 Standard from Wachendorff GmbH.

To complement its range of powerful and robust control hardware, Sensor-Technik UK introduces the Opus A6 Standard from Wachendorff GmbH. Thomas North, Calibration & Applications Engineer explains about the importance of calibration to engineers and manufacturers involved in every aspect of measuring technology.

Thomas North, Calibration & Applications Engineer explains about the importance of calibration to engineers and manufacturers involved in every aspect of measuring technology.  HBM’s on-site service is an extension of one of the best-known and most capable DAkkS standards calibration labs worldwide, which is based at HBM in Darmstadt. Its calibration service provides very high accuracy with measurement uncertainty ranging from 0.005% to 0.02% of the actual value. In addition the calibration service covers a range from 2.5 N to 5 MN for tensile and compressive force; this is the largest range available through DAkkS.

HBM’s on-site service is an extension of one of the best-known and most capable DAkkS standards calibration labs worldwide, which is based at HBM in Darmstadt. Its calibration service provides very high accuracy with measurement uncertainty ranging from 0.005% to 0.02% of the actual value. In addition the calibration service covers a range from 2.5 N to 5 MN for tensile and compressive force; this is the largest range available through DAkkS. Do you need the shortest possible push-pull cylindrical connector?

Do you need the shortest possible push-pull cylindrical connector?