Intrinsic Safety is one of a few methods available for ex-hazardous areas and is mainly used for measuring and control instruments like pressure transmitters.

Intrinsic Safety is one of a few methods available for ex-hazardous areas and is mainly used for measuring and control instruments like pressure transmitters.

The term hazardous area can be confusing. Hazardous area refers to any location with combustible material such as gases, dusts, or fibres that might produce an ignitable mixture. A hazardous area can be a sealed room filled with a volatile material or an area that is open to normal foot traffic, such as the area around a gas pump.

A device termed intrinsically safe is designed to be incapable of producing heat or spark sufficient to ignite an explosive atmosphere. Intrinsic safety (IS) is a protection technique that works by limiting the energy available for ignition. Devices or wiring are not intrinsically safe alone, only when employed in a properly designed IS system. Such systems are usually provided with detailed instructions to ensure safe use and maintenance. A measuring instrument certified for use in a hazardous area will be designed to operate with low voltage and current, and will be designed without any large capacitors or inductors that could discharge in a spark. The instrument will be connected, using approved wiring methods, back to a control panel in a non-hazardous area that contains safety barriers. The safety barriers ensure that no accidental contact occurs between the instrument circuit and outside power sources. No more than the approved voltage or current enters the hazardous area.

The most important advantage of intrinsic safety is that it is the only technique that is allowed to be used under Zone 0/20 of the IEC Classification system for hazardous areas. Other techniques like explosion proof (Exd) or any of the many other methods of protection cannot be used in Zone 0/20.

Overall, intrinsic safety is the safest, least expensive, and easiest-to-install method of protection available. With intrinsic safety, system integrity is not a concern because explosions cannot occur. Low energy requirements eliminate shock hazards and safety “hot” permits so field instruments can be calibrated and maintained while power is on. The affinity to newer technology is one reason intrinsic safety is becoming the dominant protection method.

Overall, intrinsic safety is the safest, least expensive, and easiest-to-install method of protection available. With intrinsic safety, system integrity is not a concern because explosions cannot occur. Low energy requirements eliminate shock hazards and safety “hot” permits so field instruments can be calibrated and maintained while power is on. The affinity to newer technology is one reason intrinsic safety is becoming the dominant protection method.

ESI Technology has a range of ATEX and IECEx pressure transmitters designed for use in hazardous areas. All of our intrinsically safe pressure sensors provide a 4-20mA output.

Our ATEX/ IECEx pressure sensors are available in gauge, absolute, vacuum and differential pressure measurement format. Custom pressure ranges are also available. Visit www.esi-tec.com for more details or contact our sales team sales@esi-tec.com

Our ATEX/ IECEx pressure sensors are available in gauge, absolute, vacuum and differential pressure measurement format. Custom pressure ranges are also available. Visit www.esi-tec.com for more details or contact our sales team sales@esi-tec.com

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control

Status Instruments has used state of the art technology to develop a powerful but cost effective ‘smart’ powered conditioner with features usually only found in more expensive conditioners.

Status Instruments has used state of the art technology to develop a powerful but cost effective ‘smart’ powered conditioner with features usually only found in more expensive conditioners. DJB Instruments UK Ltd has added two IEPE accessories to their range of accelerometers and instrumentation. The new VB/01 is a low cost battery powered single channel IEPE accelerometer supply which provides 4mA constant current supply at 18VDC, with LED indicators for power, short circuit and open circuit it is perfect for field testing where no mains power is available.

DJB Instruments UK Ltd has added two IEPE accessories to their range of accelerometers and instrumentation. The new VB/01 is a low cost battery powered single channel IEPE accelerometer supply which provides 4mA constant current supply at 18VDC, with LED indicators for power, short circuit and open circuit it is perfect for field testing where no mains power is available. Commenting on the new products, DJB’s Technical Manager, Gary Chadwick said ‘Though these products are far from unique we have tried to improve their cost effectiveness and the amount of sensor feedback available to the user. At the same time we have used them as the basis for new products that will create genuine progression through integrating multiple requirements into one product.’

Commenting on the new products, DJB’s Technical Manager, Gary Chadwick said ‘Though these products are far from unique we have tried to improve their cost effectiveness and the amount of sensor feedback available to the user. At the same time we have used them as the basis for new products that will create genuine progression through integrating multiple requirements into one product.’

Millions of our differential pressure and flow sensors are in operation in the field. Their industry-leading long-term stability is well proven in hundreds of different applications. The sensors come with fully calibrated digital or analog output and have the highest sensitivity and accuracy. The most recent versions feature low power consumption, extended measurement ranges, failsafe certification, and calibration for measuring mass flow in a bypass configuration.

Millions of our differential pressure and flow sensors are in operation in the field. Their industry-leading long-term stability is well proven in hundreds of different applications. The sensors come with fully calibrated digital or analog output and have the highest sensitivity and accuracy. The most recent versions feature low power consumption, extended measurement ranges, failsafe certification, and calibration for measuring mass flow in a bypass configuration. The LPG series offers the most compact liquid flow sensors available today, enabling outstanding performance and speed in the smallest of spaces. The innovative design features our highly sensitive microchip, which measures the flow in a planar microfluidic substrate from the outside of the flow channel. Fluidic ports on the bottom allow easy integration into manifold systems.

The LPG series offers the most compact liquid flow sensors available today, enabling outstanding performance and speed in the smallest of spaces. The innovative design features our highly sensitive microchip, which measures the flow in a planar microfluidic substrate from the outside of the flow channel. Fluidic ports on the bottom allow easy integration into manifold systems. Bury St. Edmunds – UK – December 2013: Switching and sensing solutions leader Herga Technology has added a new low cost all-electronic foot potentiometer that provides a variable voltage output proportional to the position of the pedal. Aimed at applications across medical equipment, domestic appliance, office and industrial machinery, the robust 6210-VO features a solid state optical sensor for wear free operation with extremely long and reliable life of more than one million operations. The unit is designed for use on manually operated equipment with control input ratings from 4.5 to 12 VDC at 10 mA, enabling precise adjustment for functions such as motor speed or torque for lifting, mixing, dispensing, cutting and sealing – and all areas where a low cost means of providing manually controlled variable functions is required for maximum productivity.

Bury St. Edmunds – UK – December 2013: Switching and sensing solutions leader Herga Technology has added a new low cost all-electronic foot potentiometer that provides a variable voltage output proportional to the position of the pedal. Aimed at applications across medical equipment, domestic appliance, office and industrial machinery, the robust 6210-VO features a solid state optical sensor for wear free operation with extremely long and reliable life of more than one million operations. The unit is designed for use on manually operated equipment with control input ratings from 4.5 to 12 VDC at 10 mA, enabling precise adjustment for functions such as motor speed or torque for lifting, mixing, dispensing, cutting and sealing – and all areas where a low cost means of providing manually controlled variable functions is required for maximum productivity. On May 6, a rocket will lift off bound for the International Space Station (ISS). On board will be a liquid flow sensor from Sensirion AG, Stäfa, Switzerland. The sensor is part of a research project by Minnehaha Academy in Minnesota that is investigating the impact of microgravity on the effectiveness of liquid flow. Among other potential findings, the project aims to shed light on the effects of weightlessness on the circulatory system.

On May 6, a rocket will lift off bound for the International Space Station (ISS). On board will be a liquid flow sensor from Sensirion AG, Stäfa, Switzerland. The sensor is part of a research project by Minnehaha Academy in Minnesota that is investigating the impact of microgravity on the effectiveness of liquid flow. Among other potential findings, the project aims to shed light on the effects of weightlessness on the circulatory system.

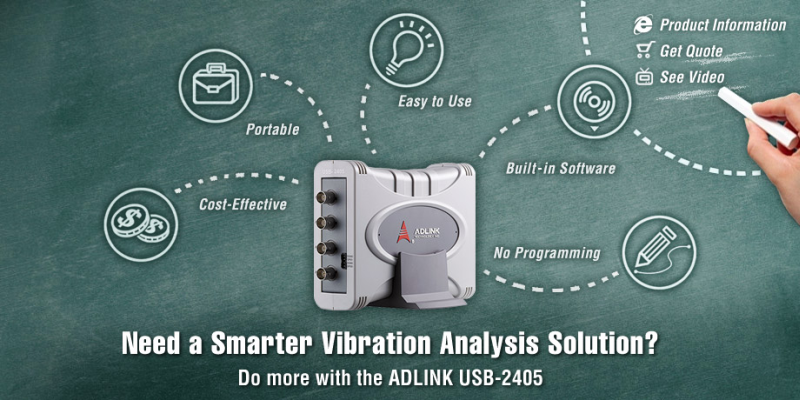

Combining high accuracy, excellent performance, and powerful analysis application Visual Signal DAQ Express, the USB-2405 is the best choice for a portable time-frequency spectrum analyzer for machine diagnostics and failure prevention, research, and portable field measurement, and especially for handheld meter and benchtop analysis users who seek improved performance and functionality while conserving costs while maintaining basic analysis capability, such that projects are expedited easily and efficiently.

Combining high accuracy, excellent performance, and powerful analysis application Visual Signal DAQ Express, the USB-2405 is the best choice for a portable time-frequency spectrum analyzer for machine diagnostics and failure prevention, research, and portable field measurement, and especially for handheld meter and benchtop analysis users who seek improved performance and functionality while conserving costs while maintaining basic analysis capability, such that projects are expedited easily and efficiently. The range of wireless sensors from Industrial Interface allow the value of virtually any process parameter to be transferred wirelessly to a range of receiver units. These receiver units can either re-form the parameter as a 4-20mA or digital contact output or hold the values in Modbus registers to be read by any RS232/485 or industrial Ethernet Communications network.

The range of wireless sensors from Industrial Interface allow the value of virtually any process parameter to be transferred wirelessly to a range of receiver units. These receiver units can either re-form the parameter as a 4-20mA or digital contact output or hold the values in Modbus registers to be read by any RS232/485 or industrial Ethernet Communications network. Brownell has introduced an Electronic Relative Humidity Indicator as an alternative to paper and chemical colour based indicators.

Brownell has introduced an Electronic Relative Humidity Indicator as an alternative to paper and chemical colour based indicators. HBM On Tour 2014

HBM On Tour 2014