New from Retriever Technology is the PLAN-FOR-ACTION scheduling software program.

New from Retriever Technology is the PLAN-FOR-ACTION scheduling software program.

It provides a simple means of producing routine action plans and schedules, emailing these to the relevant parties and recording the results for compliance and traceability purposes.

It does not include complicated facilities for producing works orders, parts lists, workshop manuals, technical drawings and procedures and similar items – it is designed to be easy to use with a relatively small number of screens and not too much detail – just sufficient to do the job.

Also it is applicable to a wide range of routine activities such as maintenance, servicing, training, auditing, highways and building inspection, calibration, testing, quality control, renewals, PAT testing, subscriptions, birthdays and so on.

The system enables you to generate regular action schedules, email these to the relevant people with optional worksheets attached and record the results for compliance and traceability purposes.

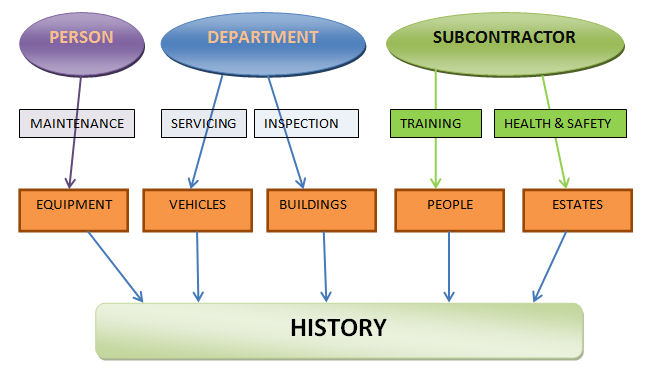

The system is built on a framework of 4 elements:

- ASSETS: the things and/or people that are the objects of the actions

- ACTIONS: what has to be done with optional itemised lists

- AGENTS: the person or organisations that take the actions

- HISTORY: historical dated records of actions taken

Each asset can be linked to one or more actions, each with an agent and a frequency. The system computes the next action due dates automatically using the historical records.

Schedules are generated based sets of assets filtered by location, type, action and target period. These schedule can be viewed, printed and emailed and are stored in the system until the results of the relevant actions have been recorded. Schedule templates are used to generate repeat schedules such as weekly, monthly or annual lists for selected asset groups.

All reports in the system can be generated as Microsoft EXCEL spreadsheets or PDF files.

The ‘Agents’ have email addresses to receive the relevant schedules. Each asset can also have an email address to receive reminders of forthcoming activity. Worksheets can be set up for an action if required and emailed with the schedules to facilitate correct practice and recording of results and comments. External documents can be linked to the assets, actions and history. The historical records can include traceability references and document links where required.

User access is password protected and each user is allocated permissions to add/edit/delete records as appropriate by the System Administrator.

The system runs on Microsoft WINDOWS-based computers and networks and is supplied with an annual renewable licence to include technical support and updates either on a single-user or a site-wide basis.

Retriever Technology: www.plan-for-action.com Tel: 01584-781444

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control

Sensirion AG (Switzerland), the leading manufacturer of digital microsensors, has won the DeviceMed OEM-Components innovation prize at the Compamed 2014 exhibition. The disposable liquid flow sensor LD20-2000T for medical devices convinced the jury due to the integration of a thermical sensor element in a microchip. It is based on Sensirion’s CMOSens® technology and has the size of a pinhead. The use of intelligent, compact and cost-effective disposable liquid flow sensors will enable safer, more reliable and more mobile solutions for care in the hospital and at home.

Sensirion AG (Switzerland), the leading manufacturer of digital microsensors, has won the DeviceMed OEM-Components innovation prize at the Compamed 2014 exhibition. The disposable liquid flow sensor LD20-2000T for medical devices convinced the jury due to the integration of a thermical sensor element in a microchip. It is based on Sensirion’s CMOSens® technology and has the size of a pinhead. The use of intelligent, compact and cost-effective disposable liquid flow sensors will enable safer, more reliable and more mobile solutions for care in the hospital and at home. Hansford Sensors

Hansford Sensors The Rapidox 7100 Multigas Analyser is an all new high specification instrument, designed and manufactured by Cambridge Sensotec. Developed in reaction to customer demand for a modular gas analysis instrument, the Rapidox 7100 is able to analyse, control and monitor up to six compatible gases.

The Rapidox 7100 Multigas Analyser is an all new high specification instrument, designed and manufactured by Cambridge Sensotec. Developed in reaction to customer demand for a modular gas analysis instrument, the Rapidox 7100 is able to analyse, control and monitor up to six compatible gases. The SSX and SST Safety Isolators and Splitters have received the 2014 Safety Award for Interface Modules from exida, the global leader in functional safety certification for the process industries. The SSX/SST family is one of three products to receive the recognition, which highlights products that bring innovation to the concept of Functional Safety.

The SSX and SST Safety Isolators and Splitters have received the 2014 Safety Award for Interface Modules from exida, the global leader in functional safety certification for the process industries. The SSX/SST family is one of three products to receive the recognition, which highlights products that bring innovation to the concept of Functional Safety. A revised and expanded catalogue of fixtures, grips and testing accessories is now available from Mecmesin.

A revised and expanded catalogue of fixtures, grips and testing accessories is now available from Mecmesin. Reliable and repeatable force and torque testing depends entirely on appropriate fixturing. Mecmesin designs, manufactures, and sources the best quality accessories for all applications, meeting the exacting requirements of industry and international standards. From highly-specified methods for peel and adhesion, or coefficient of friction, to rigorous internally-specified standards and applications, we meet the needs of users, however diverse.

Reliable and repeatable force and torque testing depends entirely on appropriate fixturing. Mecmesin designs, manufactures, and sources the best quality accessories for all applications, meeting the exacting requirements of industry and international standards. From highly-specified methods for peel and adhesion, or coefficient of friction, to rigorous internally-specified standards and applications, we meet the needs of users, however diverse.

The AFOLUX Gen III PanelPC family announced by The BVM Group brings high-end computing capability and speed to compact, IP65 sealed rugged units, which can be embedded in other equipment to provide an advanced HMI. First of these to be released is the AFL3-W07A-BT, which features a 7 inch HD 1024 x 600 projective capacitance screen supporting multi-touch functionality and offering landscape and portrait screen modes. A very slim 2mm front bezel gives maximum screen visibility; the overall size of the stylish unit is 190 x 127 x 39mm. Based on the dual core Intel Celeron N2807 2.16 GHz processor with up to 4GB of RAM, the low power consumption ensures fanless operation without any danger of overheating, even during extended use. Windows 7 Embedded and Windows 8 OS are supported. Typical applications include factory interface, home automation controller, digital signage and stock control and picking in warehouses.

The AFOLUX Gen III PanelPC family announced by The BVM Group brings high-end computing capability and speed to compact, IP65 sealed rugged units, which can be embedded in other equipment to provide an advanced HMI. First of these to be released is the AFL3-W07A-BT, which features a 7 inch HD 1024 x 600 projective capacitance screen supporting multi-touch functionality and offering landscape and portrait screen modes. A very slim 2mm front bezel gives maximum screen visibility; the overall size of the stylish unit is 190 x 127 x 39mm. Based on the dual core Intel Celeron N2807 2.16 GHz processor with up to 4GB of RAM, the low power consumption ensures fanless operation without any danger of overheating, even during extended use. Windows 7 Embedded and Windows 8 OS are supported. Typical applications include factory interface, home automation controller, digital signage and stock control and picking in warehouses. Mining and mineral processing facilities represent significant fire and explosion hazards to both personnel and production equipment and buildings. Explosions in underground mines and surface processing facilities are caused by accumulations of flammable gas and/or combustible dust mixed with air in the presence of an ignition source.

Mining and mineral processing facilities represent significant fire and explosion hazards to both personnel and production equipment and buildings. Explosions in underground mines and surface processing facilities are caused by accumulations of flammable gas and/or combustible dust mixed with air in the presence of an ignition source. ESI technology Ltd are delighted to introduce Group 1, M1 Mining to their ATEX certification!

ESI technology Ltd are delighted to introduce Group 1, M1 Mining to their ATEX certification! Incorporating SOS into applications where ATEX approval is required offers a reliable and durable solution with unbeatable performance and value. Because the silicon is grown onto the surface of the sapphire it is incredibly stable and exhibits virtually no hysteresis. With its outstanding insulation properties, the sapphire protects the strain gauge from electromagnetic pulse radiation, and allows the sensor to operate over a very wide temperature range without loss of performance. It can endure high over pressures and provides superb corrosion resistance. The excellent elasticity of the sapphire ensures high repeatability which is a highly desirable characteristic for sensors. SOS technology is incorporated into the ESI ATEX portfolio through a range of high standard products.

Incorporating SOS into applications where ATEX approval is required offers a reliable and durable solution with unbeatable performance and value. Because the silicon is grown onto the surface of the sapphire it is incredibly stable and exhibits virtually no hysteresis. With its outstanding insulation properties, the sapphire protects the strain gauge from electromagnetic pulse radiation, and allows the sensor to operate over a very wide temperature range without loss of performance. It can endure high over pressures and provides superb corrosion resistance. The excellent elasticity of the sapphire ensures high repeatability which is a highly desirable characteristic for sensors. SOS technology is incorporated into the ESI ATEX portfolio through a range of high standard products. The SSX and SST Safety Isolators and Splitters have received the 2014 Safety Award for Interface Modules from exida, a global brand in functional safety certification for the process industries. The SSX/SST family is one of three products to receive the recognition, which highlights products that bring innovation to the concept of Functional Safety.

The SSX and SST Safety Isolators and Splitters have received the 2014 Safety Award for Interface Modules from exida, a global brand in functional safety certification for the process industries. The SSX/SST family is one of three products to receive the recognition, which highlights products that bring innovation to the concept of Functional Safety. When Crowcon wanted to design and develop a new fully automated,

When Crowcon wanted to design and develop a new fully automated,  42T’s broad experience of manufacturing innovation made them an ideal

42T’s broad experience of manufacturing innovation made them an ideal  In another project, 42 Technology engineered a

In another project, 42 Technology engineered a  Finally, 42T was able to help Talaris in the development of a

Finally, 42T was able to help Talaris in the development of a