It’s difficult to tell you quickly all what’s possible with the range of data loggers available from the Test Tools Shop. We actually need you to come up with the potential measurement problems and then our experts will find a suitable solution specifically for you. We offer simple single channel data loggers for the measurement of variables such as voltage, current and temperature right up to instruments capable of monitoring 100’s of variables. Just take a look at a few of the customer problems that we resolved starting off by going Underground!

You can check out our full range of data loggers here but remember we really want to hear from you, our engineers would love to help you solve your test & measurement problems!

Data Loggers

And here are a few of our existing customer who gave us a problem to solve!

Test Tools Shop going Underground with Tube Lines.

When Tube Lines needed to upgrade the battery systems on its underground Tube Stock (1973 Tube Stock) their initial priority was to monitor the existing and new battery systems to better understand how the battery’s actually performed under the daily load profile of an operational tube train on the Piccadilly Line.

When Tube Lines needed to upgrade the battery systems on its underground Tube Stock (1973 Tube Stock) their initial priority was to monitor the existing and new battery systems to better understand how the battery’s actually performed under the daily load profile of an operational tube train on the Piccadilly Line.

Tube Lines needed to monitor the load characteristics placed on the battery system, this included charging at 50V DC via the motor alternators and then the effect of direct DC loads which could include; the lighting systems, heaters, traction equipment, door controls, braking systems and radio communications.

There was a requirement to record real time data in four locations within the tube train. Two temperature points including ambient temperature and battery compartment temperatures needed to be monitored, battery terminal voltages at 4 locations and both charging and discharge battery loads. Temperature monitoring was carried out via temperature transmitters with a DC voltage output, charging/discharge battery voltages could be monitored directly and the DC charge/discharge current was monitored via 16 specially designed Hall Effect current probes from our partner GMC-I Prosys. All of the measurement signals were then feed into and recorded by four Hioki 10 channel compact data loggers ‘Secretly Concealed’ in 4 locations on each tube train to be monitored!

Over a six week period Tube Lines were able to complete a battery load profile for the tube trains running on the Piccadilly line at different times, days and under different working conditions this base line development work will help Tube Lines monitor the performance of the new battery system over the long term.

Pressure Testing Pipeline systems supported by Microedge data loggers.

MACAW Engineering is a leading independent engineering consultancy, working with global operators of oil & gas production facilities, pipelines and utility systems to reduce risk, maintain integrity and extend the service life of their client’s assets.

MACAW Engineering is a leading independent engineering consultancy, working with global operators of oil & gas production facilities, pipelines and utility systems to reduce risk, maintain integrity and extend the service life of their client’s assets.

MACAW’s engineering capabilities cover high pressure steel transmission pipelines, low pressure cast iron and polyethylene distribution networks. They offer hydrostatic & pneumatic pressure testing up to 1200 bar covering all parts of the associated pipelines, joints and assemblies. During the tests procedures they have to monitor both flow and pressure at several test points using a range of existing pressure and flow transducers.

MACAW engineers were looking for a simple compact industrial data logger to record their test results. They needed a multichannel data logger to monitor the DC voltage output from the flow and pressure transducer over a stipulated time frame and then via simple software they needed to programme different engineering units against the DC voltage input signal to facilitate the production of acceptable test reports for their clients.

GMC Instrumentation quickly reviewed MACAW’s requirements and found the ideal solution from the Microedge SITE-LOG range of industrial data loggers.

Monitoring Gas Turbines at 188MW Combined Heat & Power Plant.

The PX Group are a specialist support company, they play a key role in the management of strategic assets for many leading companies. In this application the PX Group are responsible for the operational and maintenance support for a large 188MW Combined Heat and Power Plant and they found a great application for the Hioki LR8431-20 Memory HiLOGGER the world’s most compact 10 Channel Data logger.

The PX Group are a specialist support company, they play a key role in the management of strategic assets for many leading companies. In this application the PX Group are responsible for the operational and maintenance support for a large 188MW Combined Heat and Power Plant and they found a great application for the Hioki LR8431-20 Memory HiLOGGER the world’s most compact 10 Channel Data logger.

Engineers working on this CHP plant needed to record the results from frequency response testing carried out on the CHP gas turbines and capture the data showing how the generators would respond to support changes in the grid frequency above and below the required 50Hz. This is a key requirement of the National Grid’s Code of Compliance. The test was performed by injecting a ‘frequency deviation signal’ into the turbines governor system and recording the response. The signals that needed to be monitored were picked up from the governor’s control system and consisted of two 4 to 20mA signals and six 0 to 10V dc signals.

The initial brief from the PX group engineer was as follows

“The logger must be able to record 0-10v dc signals and a 4-20mA signal, have sample rate of 100mS and importantly, be able to export the data in an Excel spreadsheet format. A series of tests might go on for 10 hours”.

This requirement was easily meet with the Hioki LR8431-20 10 Channel Data logger. This compact portable instrument is easy to set up to record both 4 to 20mA and 0 to 10V DC signals and even with all 10 channels recording at a sample rate of 100ms continuous recording could be achieved for up to 65 days! The engineer was also able to download the recorded data in csv format and then produce an Excel spreadsheet just as he had requested.

The engineer’s final comments were;

“The logger was excellent and did everything and more than expected. It was easy to set up and connect into the system for measurement. A great piece of equipment and a very reasonable price”.

Temperature Logging in an Explosion Risk Area

We received an interesting enquiry from Omni Instruments a specialist supplier of data logging solutions, they needed a data logger to monitor temperature measurements at up to 30 test points on an oil platform. Sounds simple but petrochemical plants of any type are potentially hazardous environment and thus test equipment is strictly controlled and assessed for suitability, many instrumentation products have to be supplied as either intrinsically safe or within explosion proof enclosures.

We received an interesting enquiry from Omni Instruments a specialist supplier of data logging solutions, they needed a data logger to monitor temperature measurements at up to 30 test points on an oil platform. Sounds simple but petrochemical plants of any type are potentially hazardous environment and thus test equipment is strictly controlled and assessed for suitability, many instrumentation products have to be supplied as either intrinsically safe or within explosion proof enclosures.

In this application Omni Instruments needed a unit that could be sealed within an explosion proof enclosure and then be accessible via a USB interface, from here with the aid of a special intrinsically safe USB drive they could transfer the data to a safe area for download. The USB interface on the Hioki LR8400-20 multi-channel logger solved this problem for them.

The next problem was how to turn the Hioki LR8400-20 multi-channel logger on and off while sealed within the explosion proof enclosure. This was achieved by using a standard stop/start feature on the unit that enables it to automatically recommence recording when power is re-connected after a power failure. The clever bit here is that each time the power is switched off and then back on the unit automatically recommences logging and a new recorded data file is started with a new and consecutive filename. This enabled Omni to simply control the recording sessions by controlling the power to the unit. As soon as the power is switched back on, the recording will recommence. Omni instruments also introduced a timer into the power control circuit to allow timed logging intervals to be set.

GMC Instrumentation solved a few technical problems for the Omni Instrument engineers but we also really appreciate all their effort and expertise in utilizing the Hioki LR8400-20 in such an interesting application. We now look forward to supporting Omni Instruments on future projects.

Lovely Little Loggers solve testing problems for Environmental Compliance

Environmental Compliance Ltd recently placed another order with us for the Hioki LR5031 Instrumentation Loggers. This prompted our Director Mark to ask the question; what are you using these lovely little loggers for?

Environmental Compliance Ltd recently placed another order with us for the Hioki LR5031 Instrumentation Loggers. This prompted our Director Mark to ask the question; what are you using these lovely little loggers for?

Environmental Compliance confirmed, “We use these loggers to record the output from our FID’s” That’s great Mark thought, thanks! A quick chat around the office and we quickly realised that the problem was we didn’t have a clue what an FID was! OK Googles a wonderful little tool and a quick investigation told us that an FID is in fact a “Flame Ionization Detector”. Next question, what’s a bloody “Flame Ionization Detector” a few more minutes on Google and we were pulling up pictures, data sheets, white papers and suddenly we know all we need to know about Gas Chromatography and Flame Ionization Detectors and yes we were now experts!

To cut a long story short all we really needed to know was that these FID’s transmit a mA signal that our lovely little loggers just love to log. The Hioki LR5031 Instrumentation Loggers are set up on site by Environmental Compliance engineers and are left logging the FID’s signal output for 2…24 hours this gives the engineers all the recorded data that they need. Environmental Compliance stated that they seem ideally suited for this purpose. Thanks’ guys!

We know we are here to help our customers and we do try our best, but we also appreciate that most of what we know we have learnt whilst serving our customers!

To check out the full range of products offered by the Test Tools Shop please just click on the link below.

www.testtoolsshop.com

Test Tools Shop

Tel: 01543 469517

Fluke, the global leader in portable electronic test and measurement technology, is offering a series of free Thermography Seminars as part of its programme of seminars for 2015 in the UK and Ireland. Designed to look at the benefits of thermal imaging techniques to improve maintenance practices, the seminars are one element of the Fluke Academy programme which can be seen at http://www.flukeacademy.shuttlepod.org/UK-seminars

Fluke, the global leader in portable electronic test and measurement technology, is offering a series of free Thermography Seminars as part of its programme of seminars for 2015 in the UK and Ireland. Designed to look at the benefits of thermal imaging techniques to improve maintenance practices, the seminars are one element of the Fluke Academy programme which can be seen at http://www.flukeacademy.shuttlepod.org/UK-seminars Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control

RS Hydro have the largest flow meter rental fleet in Europe. Our range of clamp on flow meters can measure most liquids to provide velocity, energy, mass and volumetric data. Our ultrasonic flow meters are non-invasive and can be installed within minutes.

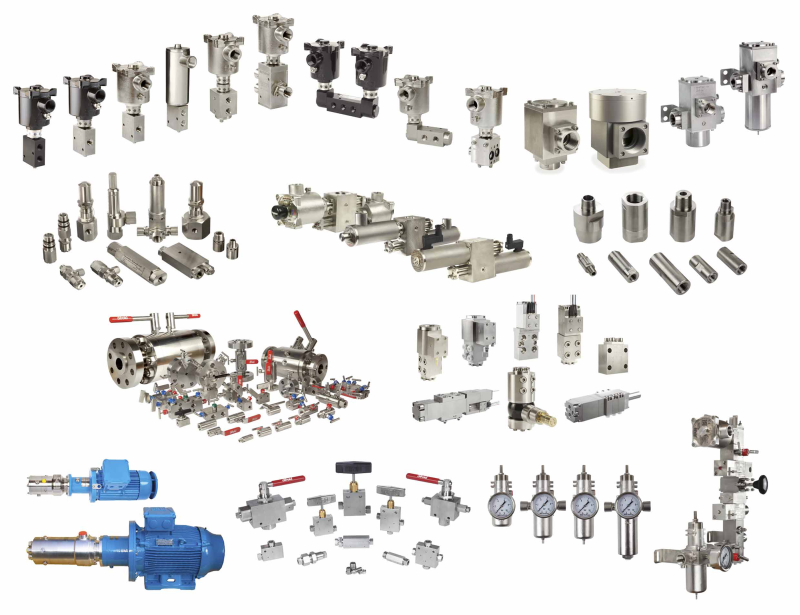

RS Hydro have the largest flow meter rental fleet in Europe. Our range of clamp on flow meters can measure most liquids to provide velocity, energy, mass and volumetric data. Our ultrasonic flow meters are non-invasive and can be installed within minutes.  Global flow control company Rotork has announced the acquisition of the Bifold Group Ltd. (Bifold), a leading manufacturer of pneumatic and hydraulic instrument valves and components.

Global flow control company Rotork has announced the acquisition of the Bifold Group Ltd. (Bifold), a leading manufacturer of pneumatic and hydraulic instrument valves and components. Quantitech, the Milton Keynes based analytical instrumentation specialist, has reported a surge in demand for its rentable emissions analysers. The company’s Dominic Duggan says: “This is undoubtedly for two reasons; first and foremost, the two main analysers are MCERTS approved and secondly, they are both transportable and simple to carry from one site to the next.”

Quantitech, the Milton Keynes based analytical instrumentation specialist, has reported a surge in demand for its rentable emissions analysers. The company’s Dominic Duggan says: “This is undoubtedly for two reasons; first and foremost, the two main analysers are MCERTS approved and secondly, they are both transportable and simple to carry from one site to the next.” Process controls and instrumentation specialists

Process controls and instrumentation specialists  BEKO TECHNOLOGIES have extended the METPOINT BDL graphic-display recorders series with a mobile variant for data logging in compressed-air and compressed-gas applications. The new METPOINT BDL portable will complete the stationary standard and compact versions of the successful measurement equipment series.

BEKO TECHNOLOGIES have extended the METPOINT BDL graphic-display recorders series with a mobile variant for data logging in compressed-air and compressed-gas applications. The new METPOINT BDL portable will complete the stationary standard and compact versions of the successful measurement equipment series. Non contact radar level sensors increase reliability on river sluices for Canal & River Trust

Non contact radar level sensors increase reliability on river sluices for Canal & River Trust As a result Canal & River Trust have installed two other devices alongside, VEGAPULS WL61 water radars, as test instruments. As they are unaffected by weather or surface conditions, these were simply mounted on a “unistrut” adjacent to the stilling tubes and CRT have compared the data from both sets of instruments over several months. There has been no “drift” with the WL61 water radars since installation. “Whilst we have seen occasions where the water level on one or both of the ultrasonic units rises, the radars have not.” Continues the engineer. “As far as I can see, the WL61 radars provide more reliable data than the ultrasonic devices. My concern with the ultrasonic sensors is that “drift” could create nuisance alarms and result in staff call outs.” There are also the ongoing maintenance requirements associated with the stilling tubes. “I do not have these concerns with the WL61s. In addition, I have confidence in the support from VEGA should an issue arise with any of the instruments at a later date.”

As a result Canal & River Trust have installed two other devices alongside, VEGAPULS WL61 water radars, as test instruments. As they are unaffected by weather or surface conditions, these were simply mounted on a “unistrut” adjacent to the stilling tubes and CRT have compared the data from both sets of instruments over several months. There has been no “drift” with the WL61 water radars since installation. “Whilst we have seen occasions where the water level on one or both of the ultrasonic units rises, the radars have not.” Continues the engineer. “As far as I can see, the WL61 radars provide more reliable data than the ultrasonic devices. My concern with the ultrasonic sensors is that “drift” could create nuisance alarms and result in staff call outs.” There are also the ongoing maintenance requirements associated with the stilling tubes. “I do not have these concerns with the WL61s. In addition, I have confidence in the support from VEGA should an issue arise with any of the instruments at a later date.” Moore Industries’ early experience with the EMPHASIS assessment tool in the United Kingdom has helped to refine the company’s approach to building products designed for functional safety and use in the global and UK nuclear industry. The company has been assessed against and used the EMPHASIS tool to achieve approval for four smart instruments with a fifth instrument currently in the approval process.

Moore Industries’ early experience with the EMPHASIS assessment tool in the United Kingdom has helped to refine the company’s approach to building products designed for functional safety and use in the global and UK nuclear industry. The company has been assessed against and used the EMPHASIS tool to achieve approval for four smart instruments with a fifth instrument currently in the approval process. Moore Industries worked with the Control and Instrumentation Nuclear Industries Forum (CINIF) in the UK on the conceptual development of the EMPHASIS assessment tool for smart instruments intended for use in nuclear safety-critical applications in the UK. Released in 2005, EMPHASIS provides a common framework for determining the suitability of devices in nuclear industries. Earlier designs for process control and safety systems used “good engineering practices and experience” as guidelines. As functional safety awareness grew and software-based products became more complex, standards such as IEC 61508 evolved to create more comprehensive guidelines for implementing safety.

Moore Industries worked with the Control and Instrumentation Nuclear Industries Forum (CINIF) in the UK on the conceptual development of the EMPHASIS assessment tool for smart instruments intended for use in nuclear safety-critical applications in the UK. Released in 2005, EMPHASIS provides a common framework for determining the suitability of devices in nuclear industries. Earlier designs for process control and safety systems used “good engineering practices and experience” as guidelines. As functional safety awareness grew and software-based products became more complex, standards such as IEC 61508 evolved to create more comprehensive guidelines for implementing safety. Detecting vibrations in machines, vehicles or buildings is an integral part of the structural analysis and fatigue test. The new measurement module A111 in the product family Q.series allows the signal acquisition of four IEPE sensors. All inputs are galvanically isolated and therefore very resistant to interference and robust. For much dynamic the four 100 kHz A / D converters provide bit with a resolution of the 24bit. Several measuring ranges and filter options to meet the requirements of vibration analysis.

Detecting vibrations in machines, vehicles or buildings is an integral part of the structural analysis and fatigue test. The new measurement module A111 in the product family Q.series allows the signal acquisition of four IEPE sensors. All inputs are galvanically isolated and therefore very resistant to interference and robust. For much dynamic the four 100 kHz A / D converters provide bit with a resolution of the 24bit. Several measuring ranges and filter options to meet the requirements of vibration analysis. When Tube Lines needed to upgrade the battery systems on its underground Tube Stock (1973 Tube Stock) their initial priority was to monitor the existing and new battery systems to better understand how the battery’s actually performed under the daily load profile of an operational tube train on the Piccadilly Line.

When Tube Lines needed to upgrade the battery systems on its underground Tube Stock (1973 Tube Stock) their initial priority was to monitor the existing and new battery systems to better understand how the battery’s actually performed under the daily load profile of an operational tube train on the Piccadilly Line. MACAW Engineering is a leading independent engineering consultancy, working with global operators of oil & gas production facilities, pipelines and utility systems to reduce risk, maintain integrity and extend the service life of their client’s assets.

MACAW Engineering is a leading independent engineering consultancy, working with global operators of oil & gas production facilities, pipelines and utility systems to reduce risk, maintain integrity and extend the service life of their client’s assets. The PX Group are a specialist support company, they play a key role in the management of strategic assets for many leading companies. In this application the PX Group are responsible for the operational and maintenance support for a large 188MW Combined Heat and Power Plant and they found a great application for the

The PX Group are a specialist support company, they play a key role in the management of strategic assets for many leading companies. In this application the PX Group are responsible for the operational and maintenance support for a large 188MW Combined Heat and Power Plant and they found a great application for the  We received an interesting enquiry from Omni Instruments a specialist supplier of data logging solutions, they needed a data logger to monitor temperature measurements at up to 30 test points on an oil platform. Sounds simple but petrochemical plants of any type are potentially hazardous environment and thus test equipment is strictly controlled and assessed for suitability, many instrumentation products have to be supplied as either intrinsically safe or within explosion proof enclosures.

We received an interesting enquiry from Omni Instruments a specialist supplier of data logging solutions, they needed a data logger to monitor temperature measurements at up to 30 test points on an oil platform. Sounds simple but petrochemical plants of any type are potentially hazardous environment and thus test equipment is strictly controlled and assessed for suitability, many instrumentation products have to be supplied as either intrinsically safe or within explosion proof enclosures. Environmental Compliance Ltd recently placed another order with us for the

Environmental Compliance Ltd recently placed another order with us for the