When a Scandinavian pharmaceutical company needed to maintain vacuum calibration accuracy whilst minimising downtime, UK pressure and gas flow measurement specialists Chell Instruments stepped in with their innovative CalCube.

When a Scandinavian pharmaceutical company needed to maintain vacuum calibration accuracy whilst minimising downtime, UK pressure and gas flow measurement specialists Chell Instruments stepped in with their innovative CalCube.

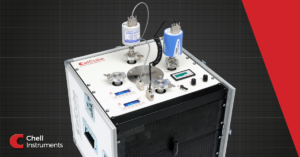

Originally developed as a general-purpose calibration stand for use in laboratories, the CalCube is a portable vacuum calibration solution which can calibrate any suitable vacuum system. It has now carved out a new niche calibrating freeze dryer vacuum instrumentation in pharmaceutical plants.

“Accuracy is of key importance when making life-changing medication” states Jamie Shanahan, Sales Director of Chell Instruments. “For pharmaceutical factories, calibration has historically meant shutting down production, dismantling sensitive measurement equipment and sending it off for calibration. Not anymore!”

The CalCube’s adaptability came to the fore when a global pharmaceutical firm with production based in Sweden contacted Chell for help. They’d spotted the CalCube’s potential when looking to avoid the costly shut-down of vacuum freeze dryers on a critical production line.

“I flew to Sweden to help their technical and engineering staff understand its versatility” continues Jamie. “They were soon wheeling the CalCube up to each device and calibrating them in situ with minimal disruption. What normally halts production for days, took just hours.”

Calibration technicians can simply move the unit to any freeze dryer, mount the gauges on to the CalCube’s ISO calibration chamber and perform a full range calibration against the CalCube’s vacuum references, generating all test points required using the CalCube’s intuitive controls.

As well as saving time and expense, the CalCube also helped the pharmaceutical company reduce risk by including dryer control system readings in the calibration process. This eliminates the introduction of errors due to differences between the control system output and instrument raw output through A to D or D to A conversions, scaling errors and programmed-in adjustment coefficients to name a few.

Due to the on-board turbo and dry diaphragm backing pumps, the CalCube quickly pumps down to its base pressure and can start performing calibrations in minutes. It can generate any test pressure between 1×10-6 mbar and atmosphere and is compatible with most vacuum instrumentation including capacitance manometers, Pirani gauges, Ion gauges and analogue gauges.

“Flying to Sweden isn’t an everyday occurrence but its something we’re glad to do if it helps customers save time and money” concludes Jamie.

The CalCube is just one of the wide range of pressure, vacuum and gas flow measurement and control solutions which Chell Instruments produce. Internationally respected for the quality of solutions their engineers deliver, they have provided high-precision instrumentation to industries including Formula One, aerospace and pharmaceuticals for more than 40 years.

For more information on Chell Instruments please visit: www.chell.co.uk

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control