ABB’s innovative security, monitoring and communications technology has been installed on the 1,850 km Trans-Anatolian Natural Gas Pipeline (TANAP). The first phase, ‘Gas to Eskisehir’ officially opened in early summer 2018 ahead of schedule. ABB provided the security, telecommunications, SCADA main control room, containerised equipment rooms and has installed the fiber optic cable along the pipeline to contribute to this achievement.

As part of the project and for the first time in a subsea water crossing, ABB has installed a fiber optic leak detection and subsea pipeline monitoring system detecting events such as anchor drag.

Over 4,000km of fiber optic cable has been installed across challenging terrain and during difficult weather conditions. Both control and telecommunication systems data are carried along the fiber optic cable that runs the length of the pipeline. It provides a vast communications infrastructure capable of handling extremely large volumes of data and is the longest system of its kind in the world.

ABB has also been responsible for installing a single comprehensive integrated security system, which monitors the external and internal CCTV cameras and the perimeter intruder detection system of every site. This pipeline intrusion detection system covers every meter of pipeline. Incorporating over 1,300 cameras and 650 access control points, this is the largest integrated security system that ABB has installed to date.

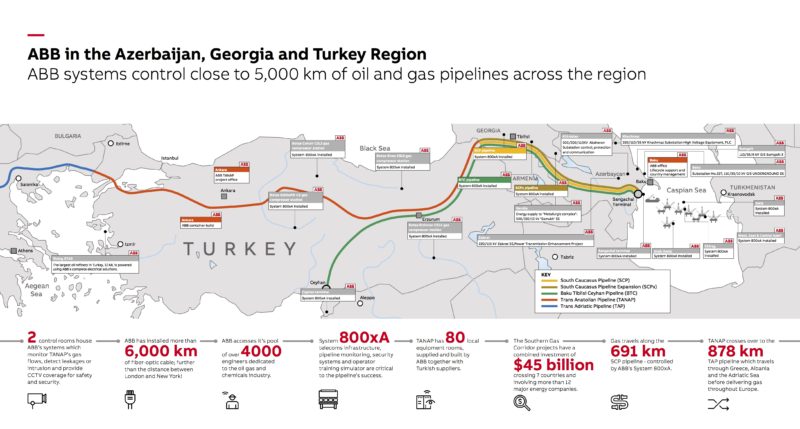

The TANAP Project brings natural gas produced from Azerbaijan’s Shah Deniz-2 gas field, and other areas of the Caspian Sea, primarily to Turkey, but also on to Europe for the first time. TANAP, along with the South Caucasus Pipeline (SCP) and the Trans-Adriatic Pipeline (TAP), form the elements of the Southern Gas Corridor. The TANAP pipeline is scheduled to complete June 2019.

Per-Erik Holsten, managing director Oil, Gas & Chemicals ABB said, “TANAP engineers were embedded within our own ABB team, helping to identify key priorities and resolve issues as they arose. This close collaboration between us ensured that the project ran smoothly – in fact ahead of schedule and on budget. With the TANAP pipeline running the entire length of Turkey and across mountainous terrain, this was no small feat. It’s been a truly joint effort to produce first gas.“

Other elements of the work that ABB completed for TANAP include:

- A robust site communication system using TETRA and interfacing all sites via the IP telephony system.

- PAGA systems integrated to the TETRA and IP Telephony systems, including 2,900 speakers

- A SCADA for overall control and monitoring of the pipeline from a remote Main Control Center (MCC). ABB also designed and delivered the MCC building.

- The MCC Control Room is duplicated at a backup control center. Using ABB‘s ‘Point of Control’ ensures the operator always knows and controls who is operating either the whole pipeline or selected assets and from where they are controlling it. This is an important safety feature for installations with multiple control rooms.

- Two leak detection systems, one using information from the same system delivered as the fiber optic based Pipeline Intrusion Detection system and one model based. The SCADA interfaces both to the fiber optic sensing system and to the model systems. The Fiber based system is also used for pig tracking information.

- ABB provided more than 50 Containerised Local Equipment Rooms to meet the demanding timescales of the project successfully

Advanced Cyber Security solutions

Instrumentation Monthly Test | Measurement | Control

Instrumentation Monthly Test | Measurement | Control